Have you ever held a perfectly sized cardboard box and wondered how it came to be? Millions of cardboard products are precisely cut daily, and the key lies in cardboard slitting machines. In this post, we'll break down the working process, from its components to the step-by-step operation.

What is a Cardboard Slitting Machine?

A cardboard slitting machine is a specialized tool used in the packaging industry to cut large rolls or sheets of cardboard into smaller, precise sizes. These machines are essential in the production of packaging materials like boxes, dividers, and other cardboard-based products.

Cardboard slitting machines work by feeding the material through the machine, where blades or lasers cut it into the desired width. The cutting process can be easily adjusted to meet different size requirements, offering great flexibility for manufacturers.

These machines are crucial for packaging and manufacturing processes. Without them, creating custom-sized cardboard products would be time-consuming and difficult. By using slitting machines, businesses can ensure consistency in their packaging while improving production efficiency and reducing waste.

Types of Cardboard Slitting Machines

Manual Cardboard Slitting Machines

Manual slitting machines are the most basic form of cardboard slitting equipment. These machines operate with minimal automation, requiring the operator to feed the cardboard and adjust settings manually. Typically, they are suitable for small-scale operations or situations where precision is not extremely critical.

Advantages:

● Low Cost: These machines are affordable and ideal for businesses just starting out.

● Simplicity: Easy to use and maintain, without the need for specialized skills.

Disadvantages:

● Low Efficiency: Slower production speed compared to more advanced models.

● Higher Margin of Error: Since they require manual adjustments, there’s a greater risk of inconsistencies in cutting.

Semi-Automatic Cardboard Slitting Machines

Semi-automatic slitting machines combine human control and automated processes. The operator is responsible for loading the cardboard and sometimes adjusting settings, but the cutting process itself is assisted by the machine. This type of machine strikes a balance between manual and fully automatic models.

These machines are perfect for medium-scale operations, where some automation is required to improve efficiency but where the volume doesn’t justify a fully automated system.

Fully Automatic Cardboard Slitting Machines

Fully automatic cardboard slitting machines are the most advanced type available. They feature a high degree of automation, with little to no human intervention required after setup. The machine automatically feeds the cardboard, cuts it to the desired size, and often stacks or packages the finished products.

These machines are highly precise and designed for high-volume production. Industries such as large-scale packaging, manufacturing, and logistics rely heavily on fully automatic machines to maintain consistency and efficiency.

Fully automatic machines are indispensable for businesses where speed, precision, and high output are crucial, ensuring minimal human error and maximizing productivity.

Key Components of a Cardboard Slitting Machine

Feeding Mechanism

The feeding mechanism is essential for placing and moving large rolls or sheets of cardboard into the machine. It ensures the material is fed consistently, which is crucial for accurate cutting.

There are different types of feeding systems:

● Roller-based systems: These use rotating rollers to push the cardboard into the machine.

● Pneumatic systems: Air pressure helps move the cardboard, offering a smoother and more controlled feed.

A stable and consistent feeding mechanism is key to achieving precise cuts. Variations in the feed can result in misalignment, which affects the cutting quality.

Cutting Mechanism

The cutting mechanism is where the cardboard is actually sliced. Different blades are used depending on the needs of the process:

● Circular blades: Ideal for continuous cutting of large rolls.

● Straight blades: Used for cutting straight lines, often in flat sheet production.

The blades are designed to cut through cardboard efficiently, and their sharpness and durability are important for maintaining consistent results. Over time, blades need to be replaced to avoid wear and tear that can affect performance. The movement of the blades varies:

● Some move perpendicular to the cardboard.

● Others may oscillate to create a smoother cut.

Guiding and Alignment Systems

Guiding and alignment systems ensure the cardboard is positioned correctly before and during the cutting process. These systems prevent misalignment or skewing, which could lead to uneven cuts.

There are different types of guiding systems:

● Mechanical guides: Physical barriers that help keep the cardboard in place.

● Sensors for automatic alignment: These detect and adjust the position of the cardboard in real-time to ensure perfect alignment.

Rewinding or Stacking Mechanism

For machines producing narrow strips, the rewinding mechanism comes into play. It rolls the cut pieces into smaller rolls. For those producing flat pieces, the stacking mechanism neatly arranges the cardboard.

Proper tension control during rewinding is crucial to prevent over-tightening, which could cause damage. When stacking, the machine ensures the pieces are aligned and orderly to prevent any shifting.

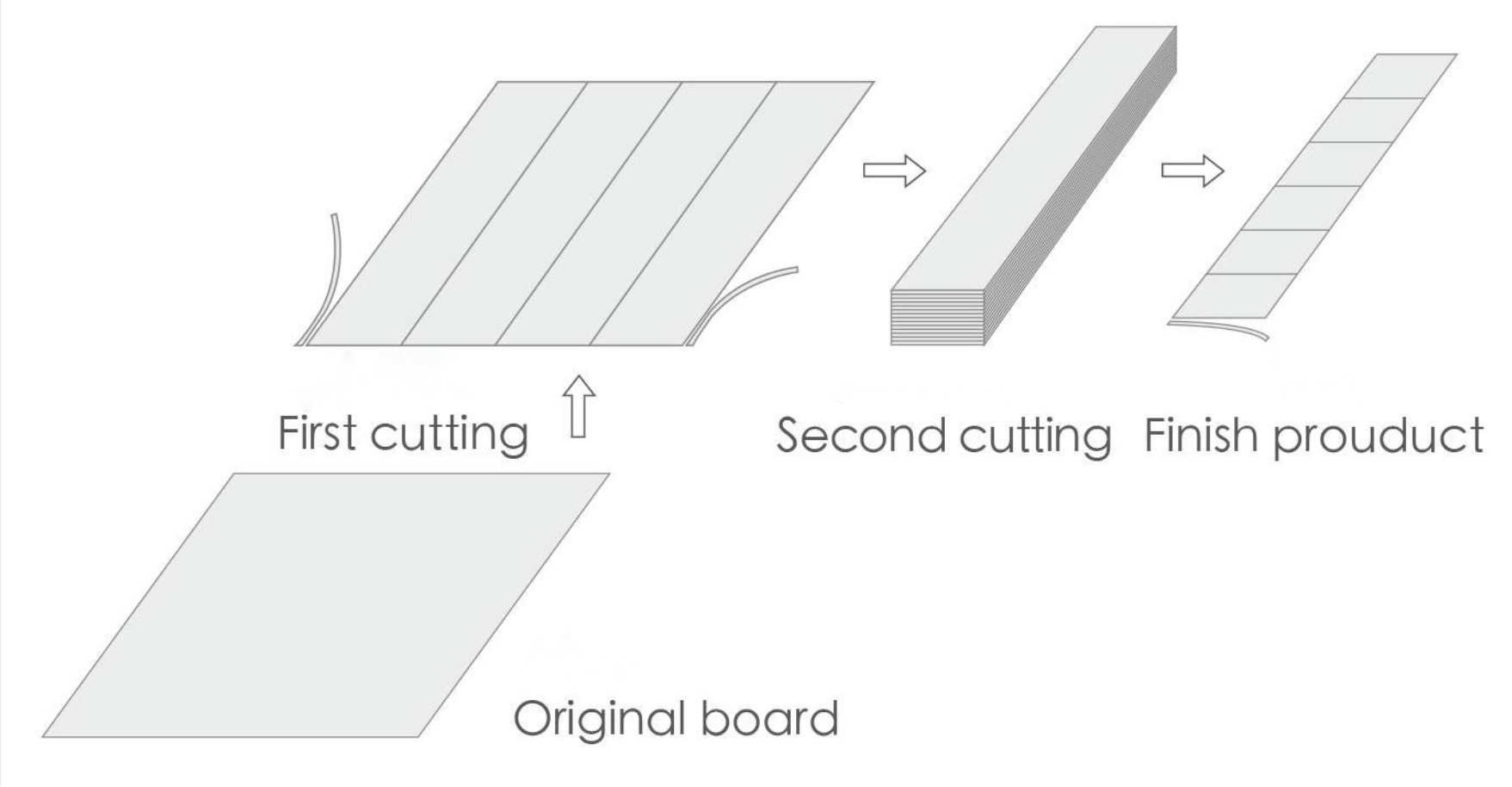

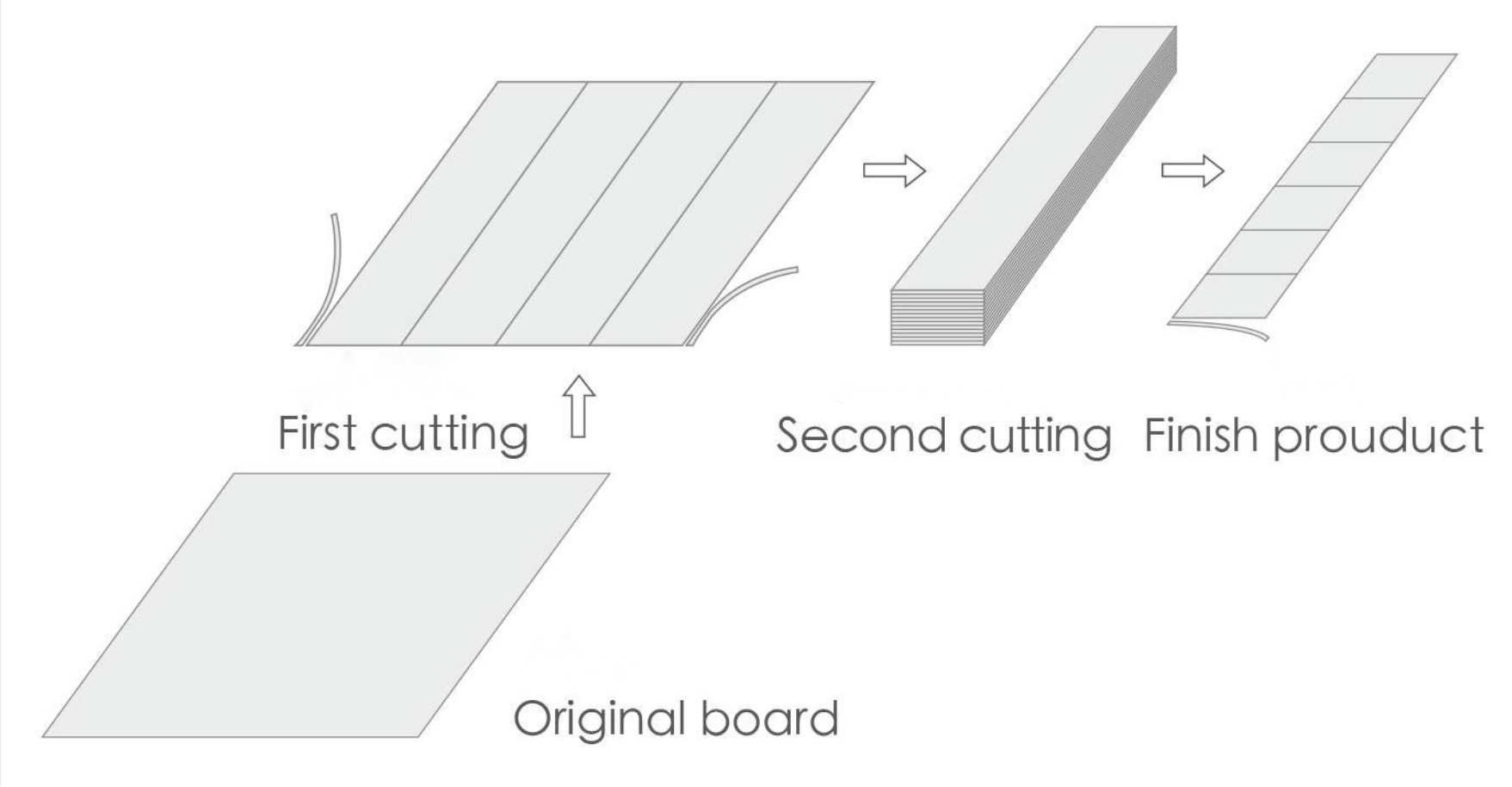

Working Principle of a Cardboard Slitting Machine

Step-by-Step Process

Material Loading

The process begins by placing large cardboard rolls or sheets onto the machine. This is a critical step, as proper loading ensures smooth operation throughout the process. Safety precautions should be followed during material loading to prevent accidents. Operators should wear protective gear and ensure the machine is powered off before loading the material.

Feeding the Cardboard into the Cutting Area

Once the material is securely placed, the feeding mechanism takes over. This mechanism moves the cardboard into the cutting area, often using rollers or pneumatic systems. The speed of the feed is controlled to maintain the correct rate for cutting, ensuring even cuts throughout the material.

Speed Control During the Feeding Process

The speed of the feeding mechanism can be adjusted to match the production needs. Slower speeds may be used for more intricate cuts, while higher speeds are suitable for bulk production. This control allows the machine to handle a variety of cardboard types and thicknesses.

The Cutting Action

Next, the cutting blades are activated. These blades slice through the cardboard as it moves forward. The interaction between the blades and the material creates precise cuts, whether the machine uses circular or straight blades. The accuracy of these cuts is essential for consistent product quality. Blades must be sharp and in good condition to ensure clean, smooth cuts.

Handling the Cut Cardboard

After cutting, the cardboard is either rewound into rolls or stacked for further processing. The rewinding mechanism ensures the cut pieces are neatly rolled, maintaining proper tension to avoid damage. In cases where flat cardboard pieces are required, the stacking mechanism arranges them neatly for easy handling.

Post-cutting operations might include edge finishing to smooth out any rough edges or quality inspection to ensure the cuts meet required standards. These processes help maintain the quality and consistency of the final product.

Control Systems in Operation

Control systems play a vital role in managing the machine's operations. Basic machines rely on manual controls, such as knobs and levers, to adjust settings like cutting width and speed. However, more advanced machines use automated control systems, like Programmable Logic Controllers (PLCs) and touch-screen interfaces, which allow for precise adjustments and easier monitoring.

Operators can adjust settings such as cutting width, speed, and blade depth through these control systems, enabling the machine to adapt to different materials and cutting requirements efficiently.

Applications of Cardboard Slitting Machines

Packaging Industry

Cardboard slitting machines play a crucial role in the packaging industry. They are widely used for:

● Production of cardboard boxes: These machines cut large sheets of cardboard into different sizes to create packaging boxes for various products.

● Creating dividers and inserts: Slitting machines help produce dividers and inserts used in packaging to protect fragile items during transportation.

● Meeting specific packaging needs: Different industries, such as food, electronics, and cosmetics, have specific packaging requirements. Slitting machines can customize cardboard sizes to fit these needs, ensuring the safety and presentation of products.

Printing and Publishing

In the printing and publishing sector, cardboard slitting machines are essential for preparing materials:

● Book covers and magazine inserts: They cut the cardboard into the precise size needed for book covers and inserts in magazines, providing sturdy, professional-quality products.

● Custom-sized cardboard for printing projects: Slitting machines are used to create custom-sized sheets for various printing jobs, ensuring the materials are the right fit for specific projects.

Other Industries

Cardboard slitting machines are not limited to just packaging and publishing. They also have several non-traditional uses, such as:

● Prototypes and DIY projects: Slitting machines can help produce cardboard for prototypes or DIY projects, giving individuals and companies flexibility in design and functionality.

Maintenance and Troubleshooting

Regular Maintenance Requirements

To keep a cardboard slitting machine running efficiently, regular maintenance is essential. This includes:

● Cleaning the machine components: Regularly removing dust, debris, and cardboard particles helps prevent buildup, ensuring smooth operation.

● Lubricating moving parts: Lubrication of gears, rollers, and other moving components reduces wear and tear, extending the machine's lifespan.

● Blade inspection and replacement: Regular checks on blade sharpness and condition are necessary. Dull or damaged blades should be replaced according to a scheduled maintenance plan to avoid compromising the cutting quality.

Common Issues and Solutions

While operating a cardboard slitting machine, you may encounter several issues. Here are some common problems and their solutions:

● Blades not cutting properly: This can happen if the blades are dull, misaligned, or damaged. Regular blade sharpening or replacement, along with checking for correct alignment, will help prevent this.

● Uneven feeding of cardboard: Problems with the feeding mechanism, such as misaligned rollers or a malfunctioning pneumatic system, can cause the cardboard to feed unevenly. Inspecting the feeding mechanism and making necessary adjustments can fix this.

● Issues with the rewinding or stacking mechanism: If the cut cardboard is not rewound or stacked correctly, it could be due to incorrect tension settings or a malfunctioning part. Regularly checking and adjusting tension controls will help maintain proper operation.

Safety Measures During Maintenance and Operation

When performing maintenance or operating the machine, always prioritize safety:

● Turn off the machine before maintenance: Ensure the machine is powered down to prevent accidental starts, which can cause injury.

● Wear appropriate safety gear: Always wear gloves, goggles, and any other recommended protective equipment to avoid injury from moving parts, sharp blades, or debris.

Conclusion

Cardboard slitting machines are essential in packaging and manufacturing. They feature key components like feeding, cutting, and alignment mechanisms. These machines ensure precision and efficiency across industries. Their role in increasing productivity is crucial, meeting diverse packaging needs. Looking ahead, advancements in automation, precision, and energy efficiency will continue to improve their performance and versatility.

FAQ

Q: How often should the blades of a cardboard slitting machine be replaced?

A: Blade replacement frequency depends on the usage and cardboard type. Typically, blades should be checked regularly and replaced every 2-6 months.

Q: Can a cardboard slitting machine be customized for specific cutting requirements?

A: Yes, slitting machines can be customized with different blade types, feeding systems, and cutting widths to meet specific needs.

Q: Are there any environmental benefits associated with using cardboard slitting machines?

A: Yes, they help reduce material waste by making precise cuts and optimizing the use of cardboard sheets, leading to fewer scraps and better material utilization.