Paper Bag Machine Solution: Superior Efficiency and Quality in Production

Product Overview

Our Paper Bag Making Machine is designed to streamline the production of various types of paper bags, including food paper bags, shopping bags, and more. Ideal for high-speed production of medium to large-sized paper bags, this state-of-the-art machine integrates multiple functions into a single, efficient line. From side gluing, roll folding, roll paper cutting, and bottom folding to bottom gluing, bottom forming, and bag discharge, this machine handles it all with ease.

Key Features

High Efficiency & Speed

Full Automation

Labor Cost Savings

Cutting Precision

Adaptability to Various Bag Sizes

Durability & Reliability

Industry Pain Points & Machine Solutions

Pain Points:

- Low speed

- Weak bags that can't support heavy items

- Limited customization options

Machine Solutions:

- High-speed production for fast turnaround

- Durable, reinforced bags suitable for heavy products

- Fully customizable sizes, prints, and designs

Pain Points:

- Slow packaging processes

- Need for food-safe, hygienic packaging

- High material waste

Machine Solutions:

- Fast, efficient production

- Hygienic, food-safe bags

- Reduced material waste with precision cutting

Pain Points:

- Packaging for heavy, oversized products

- Limited bag size options

- Bags prone to damage during handling

Machine Solutions:

- Produces large, durable bags for heavy items

- Adjustable to different sizes

- Reinforced for strength during handling

Customization & Flexibility

Customization Features

Highly Adaptable for Various Applications

Technical Advantages

Energy Efficiency & High Performance

High Automation

Precision Control

Intelligent Control Systems

Environmental Benefits

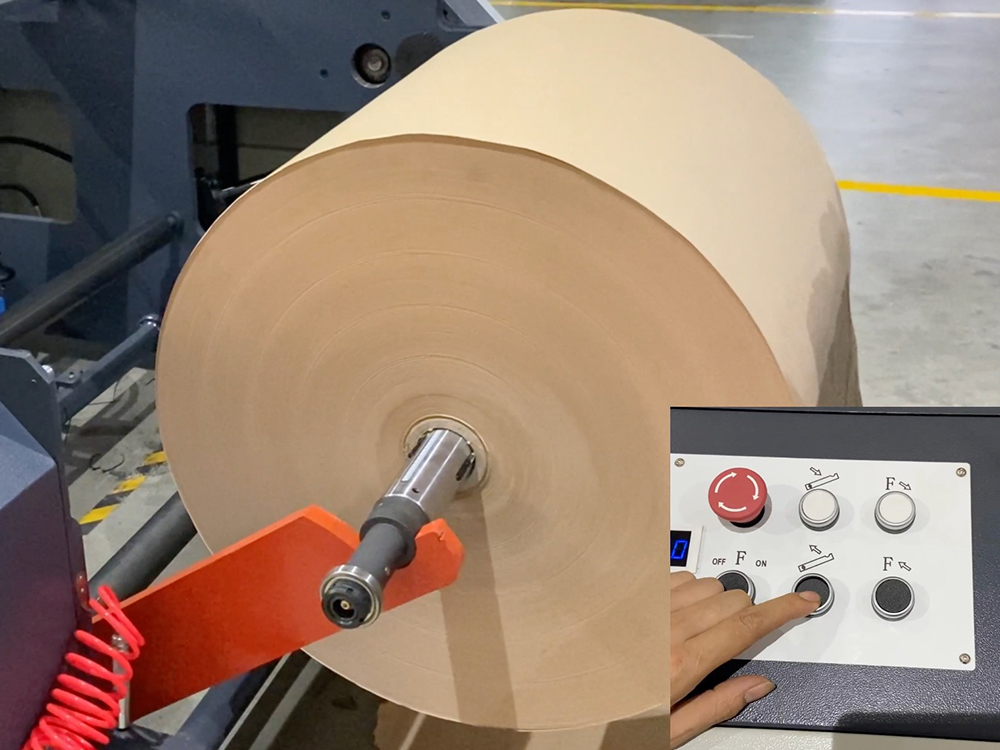

Step-by-Step Production Process

1. Paper Roll Feeding

2. Handle Insertion (Optional)

3. Side Gluing

4. Paper Cutting

5. Bottom Folding & Gluing

6. Bottom Forming

7. Bag Discharge

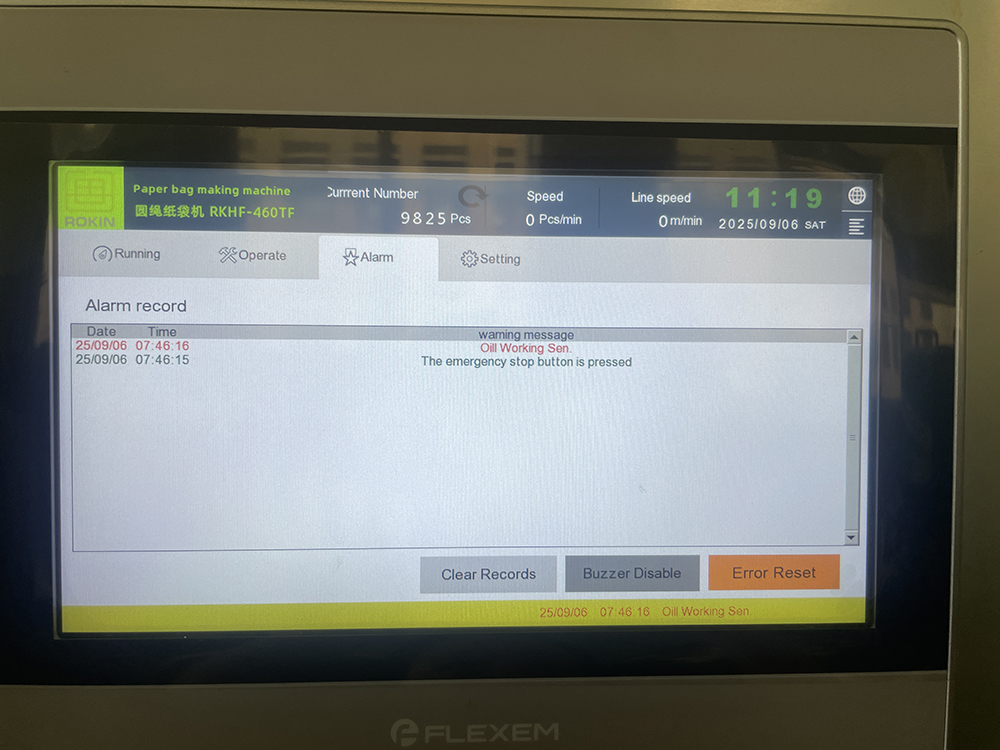

User Interface & Operation Process

The user interface of the machine is designed to be intuitive and easy to operate, even for operators with minimal technical experience:

Technical Support & Operational Efficiency

Video Demonstration of Machine Operation

FAQ

-

1. What types of paper bags can the Paper Bag Making Machine produce?

The Paper Bag Making Machine is designed to produce various types of paper bags, including food paper bags, shopping bags, and large industrial bags. It can handle different sizes and types of paper, ensuring flexibility to meet diverse customer needs.

-

2. How does the machine ensure high-quality paper bag production?

The machine utilizes precision cutting, automated gluing, and high-speed production systems to ensure consistent quality. With the help of features like the photoelectric detector, it guarantees cutting accuracy and secure bonding of handles, resulting in durable and high-quality bags.

-

3. Is the Paper Bag Making Machine easy to operate?

Yes, the machine is designed with an intuitive user interface, making it easy to set parameters such as speed, size, and adhesive application. The automated systems reduce the need for manual intervention, making it user-friendly and efficient.

-

4. Can the machine handle different types of paper and handle materials?

Absolutely! The machine is adaptable and can work with a wide variety of paper materials, including kraft paper, coated paper, and recycled paper. It also supports different handle materials, such as twisted paper, cotton, and ribbon handles, making it versatile for various industries.

-

5. What are the maintenance requirements for the Paper Bag Making Machine?

Routine maintenance is essential for optimal performance. This includes cleaning, lubricating moving parts, and inspecting for any wear and tear. The machine also provides maintenance alerts, helping operators stay on top of scheduled maintenance to avoid unexpected downtime.

Request a Free Quote

If you are interested in our products or have any questions about our product introduction, please feel free to contact us. Please provide your contact information, and our sales team will get in touch with you as soon as possible.