You can see big changes coming to paper bag making machines in 2025. Companies use new ideas, more automation, and care for the environment to do well. The table below shows some of the biggest changes:

Trend | Description |

Improved precision | Cutting and gluing is better, so there is less waste and bags are stronger. |

Advanced sensors | Sensors watch the machines in real time to make them work better. |

Modular designs | Machines can change easily to fit different jobs. |

Digital printing | Bags look nicer because of new ways to print. |

E-commerce boom | More online shopping means we need faster and better machines. |

Rokin Machinery leads the way with its advanced Machine. It helps you reach higher goals for quality and caring for the planet.

Big changes are coming to paper bag making machines by 2025. These changes will focus on automation and eco-friendly designs.

The world market for paper bag making machines may reach USD 0.566 billion. This is because more people care about the environment and new rules are being made.

Automation helps lower labor costs and makes production faster. It lets companies make more bags with less waste.

Smart manufacturing technologies, like IoT and AI, help machines work better and last longer. They make sure the bags are always high quality.

There are more ways to customize paper bags now. This helps brands make special packaging that fits what customers want.

Global Paper Bag Making Machine Market

Market Size and Forecast

The global paper bag making machine market will grow a lot in 2025. The market size is expected to be USD 0.566 billion. This is much bigger than before. More companies want to use sustainable packaging, so the market grows fast. Asia Pacific is leading this growth. China, India, and Japan are growing quickly because cities are getting bigger and more people shop in stores. This region will have a CAGR of about 8.2%. It is the fastest-growing area for paper bag making machines. North America and Europe are also important. These places have new rules that make companies use eco-friendly packaging. Rokin Machinery is a top company in this market. They make advanced machines that help companies keep up with demand.

The global paper bag making machine market could reach USD 0.566 billion in 2025.

Asia Pacific is growing fastest, with China, India, and Japan leading.

North America and Europe use new technology and green practices.

Key Growth Drivers

Many things help the paper bag making machine market grow. Governments make strict rules to cut down on plastic pollution. These rules make companies use more paper bags. Some countries give money or rewards to businesses that use green methods. This helps companies buy better machines. People care more about the environment now. They want products with eco-friendly packaging. This makes more companies buy automated and energy-saving paper bag making machines.

Strict rules lower plastic use and support paper bags.

Governments give rewards for using green manufacturing.

People like brands that use eco-friendly packaging.

The market grows as companies use advanced machines like those from Rokin Machinery. These machines work fast and make many bags each hour. This helps companies stay ahead. Machines that use recycled materials are also popular because they help the planet.

Market Restraints

There are some problems in the paper bag making machine market. New machines cost a lot, so small businesses may not afford them. Maintenance costs are also hard for small companies. There is a lot of competition, so prices and profits can go down. In places with many suppliers, it is hard to make good profits. Problems in the supply chain can make it hard to get materials or send out finished bags. New rules, like the European Union’s ban on single-use plastics, make more people want paper bags. But these rules also mean companies must change fast.

High starting costs make it hard for small businesses.

Maintenance costs are tough for smaller companies.

Strong competition lowers prices and profits.

Supply chain problems slow down production and delivery.

New rules mean companies must change quickly.

Tip: You can solve many of these problems by working with good partners and using advanced machines. Companies like Rokin Machinery have machines that help you work better and meet new needs.

Technological Advancements

Automation and Integration

Paper bag making machines work very differently now. Automation does many jobs that people did before. This lets you make more bags faster and with fewer errors. Machines now have automatic packaging, mold changes, and online visual checks. These features help keep your bags the same and high in quality.

Automatic packaging makes every bag look the same.

Automatic mold change lets you change bag sizes fast.

Online visual inspection checks each bag as it is made.

You also save money because one person can run a machine that used to need many workers. The table below shows some main benefits:

Benefit | Description |

Significant Labor Cost Reduction | One person can do the work of many, so costs go down. |

Enhanced Operational Efficiency | The machine does many steps at once, saving time and effort. |

Material Optimization & Waste Reduction | The machine uses paper well, so there is less waste. |

Rokin Machinery’s paper bag making machine is special because it combines many steps. You get side gluing, folding, cutting, and bag output all together. This makes your work faster and easier.

Tip: Automation helps you make bags quickly and keeps quality high every time.

Smart Manufacturing

Smart manufacturing uses digital tools and IoT to make work easier. With IoT, your machine sends real-time data to your computer or phone. You can watch your machine, find problems early, and fix them before they stop your work. AI and machine learning help you know when to do maintenance, so you avoid breakdowns.

Smart manufacturing also helps you control bag size and quality. You use less energy, which saves money and helps the planet. Quality control automation checks every bag, so customers get the best product.

IoT lets you watch your machine in real time.

Predictive maintenance keeps your machine working longer.

Quality control automation makes sure every bag is good.

Energy efficiency saves money and helps the environment.

Digital tools and IoT make your machine smarter. You can change settings from anywhere, get alerts if something is wrong, and use data to improve your work. This is real innovation.

Machine Versatility

You need a machine that can make many kinds of bags. Today’s machines can make grocery bags, merchandise bags, and gift bags. You can change the size and shape to fit what customers want. If you need small bags or big bags, you can adjust the machine quickly.

Make bags in many sizes and shapes.

Switch between small and big bags with easy changes.

Meet many customer needs with just one machine.

Rokin Machinery’s machines give you even more choices. You get automated controls for careful work, touch screens for easy use, and built-in printing for custom designs. This means you can do more jobs and grow your business.

Note: Machine versatility helps you keep up in a changing market. You can meet new needs without buying new machines.

Sustainability

Eco-Friendly Materials

You help the planet by picking good materials. Many companies use materials that are better for the environment. Here are some choices:

Kraft paper is strong and comes in different types. You can use it for heavy things in stores.

Recycled paper uses old paper and makes less trash. It looks natural and is liked by people who care about the earth.

Paper bags cost more than plastic bags at first. But they help brands get loyal customers and sell more. If you buy a lot, you can save money.

New machines use flexo printing with inks that are safe for the earth. Companies work with recycling plants to make recycled paper better. These steps help make packaging that is good for the planet and keeps materials in use.

Energy Efficiency

Saving energy is very important now. Machines use less power and help you spend less money. New machines have smart temperature controls and heat only where needed. Some factories use systems that save heat and power.

A plant in Ohio used 30% less electricity and made 15% more bags after getting new machines. A company in California saved $18,000 each year by using better machines.

Metric | Before Upgrade | After Upgrade | Improvement |

Energy Use (kWh/day) | 120 | 80 | 33% less |

Bags Produced (day) | 4,000 | 4,500 | 12.5% more |

Cost per Bag ($) | 0.03 | 0.02 | 33% less |

These changes help you make less pollution and use green ways. You also get better bags and spend less, so your business does well in the green market.

Regulatory Compliance

You need to follow new rules for green packaging. Governments now limit single-use plastics. The European Union and other places have strong laws to cut plastic waste. Your business needs machines that make paper bags to meet these rules.

Manufacturers must check their bags for safety and the environment. Testing and certification make sure bags are safe for food and other things. In some places, you must follow local rules to stop pollution and handle trash. By doing this, you help your business grow and show you care about making things the right way.

Paper Bag Manufacturing Trends

Retail and Food Sector Demand

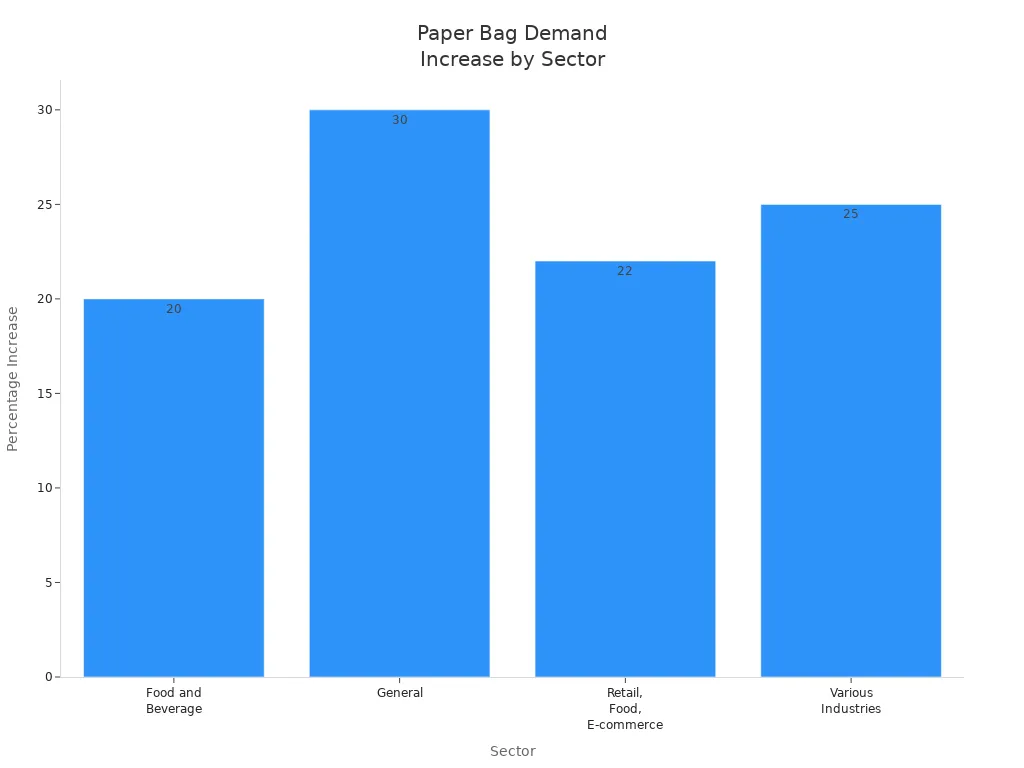

More stores and restaurants now use paper bags. People want packaging that is better for the planet. The food and drink industry is a big reason for this change. Many companies are switching from plastic to paper bags. They do this to follow new rules and make customers happy. The table below shows how much demand has grown in different areas:

Description | Percentage Increase | Sector |

Demand for paper bags in the food and beverage industry has increased due to sustainability preferences. | 20% | Food and Beverage |

Global preference for paper over plastic has risen significantly. | 30% | General |

Adoption of paper bags has risen across various industries due to regulatory actions. | 22% | Retail, Food, E-commerce |

Overall increase in the use of paper bags across industries. | 25% | Various Industries |

Rokin Machinery helps meet this demand with its machines. These machines can make shopping bags, food bags, and medical bags. You can change the settings to make different bags fast.

Customization

You want bags that match your brand and what customers need. Custom paper bags help your business stand out. Many brands print their logo or message on bags. Some bags are made stronger for heavy things. Others have special coatings to keep food safe from water. Companies now make bags in many sizes and with sections to keep things organized.

Trend | Description |

Custom Designs and Printing | Brands use custom printing to enhance identity and create memorable experiences. |

Enhanced Durability and Functionality | Modern bags carry heavier items, important for retail and food service. |

Moisture-Resistant Options | Eco-friendly coatings protect bags from humidity and keep them recyclable. |

Variety in Sizes and Compartments | Manufacturers produce bags in many sizes with compartments for organization. |

Rokin Machinery’s technology lets you make custom bags quickly. You can fill special orders and grow your business with new bag ideas.

Production Efficiency

You need machines that work fast and save money. New machines use automation and smart tools. This means you can make more bags in less time. You can watch your machines as they work and fix problems quickly. These machines can use different kinds of paper. You can make fancy gift bags or simple grocery bags. Rokin Machinery’s machines cut, glue, and fold paper very well. You spend less on workers and make more money.

Tip: Pick machines with AI and IoT to work better and fix problems easily.

Modern machines help you make more bags with less waste. You can keep up with what customers want and changes in the market.

Regional Insights

Asia-Pacific Innovation

Asia-Pacific is changing fast. Factories use automation and digitization to make machines smarter. Many factories now use AI-based monitoring systems. These systems watch machines all the time. They help you find problems before machines stop working. Predictive maintenance keeps machines running longer. This means less downtime. Modular designs let you switch bag types quickly. Multi-layer bag making helps retail and pharmaceutical sectors. IoT-based monitoring and ERP systems help manage inventory and track production. These new ideas make work easier. They also help meet the need for sustainable packaging.

North America and Europe

North America and Europe are growing fast. Both regions care about eco-friendly packaging and new technology. Europe has 36% of the market for paper-based consumer bags. Strict rules make companies use recyclable and compostable bags. North America has 28% of the market and invests in sustainability. Retail and food service need better paper bags. Many companies use kraft paper and new designs to follow rules. Waste and recycling rules affect how bags are made. Good infrastructure helps these regions use new machines quickly.

Europe has 36% of the paper-based consumer bag market.

North America has 28% and focuses on green practices.

Both regions follow strong rules and what customers want.

Emerging Markets

Emerging markets have many chances to grow. Countries in Asia Pacific, Latin America, and the Middle East & Africa are growing fast. More people care about the environment, so green packaging is needed. Governments help by making rules to cut plastic use. New tech like IoT and automation can make work better. But there are problems like unstable economies and tough rules. Trade issues and competition can lower profits. You must keep coming up with new ideas to stay ahead.

Opportunities | Challenges |

Demand for green bags | Economic instability |

Regulatory support | Regulatory hurdles |

Tech advancements | Intense competition |

Rapid industrialization | Need for innovation |

Tip: Stay flexible and keep learning about new tech. This helps you do well in different places and meet what customers want.

Competitive Landscape

Leading Manufacturers

There are many big companies in the paper bag making machine market. These companies use new technology and sell machines all over the world. Here are some of the top companies:

Windmoeller & Hoelscher (Germany) makes high-capacity machines for many countries. More than half of their machines go to North America and Asia-Pacific.

Holweg Weber (France) sells many automated square bottom machines. Their machines are used in over 60 countries.

Newlong Industrial makes almost half of the world’s high-speed paper bag machines.

Rokin Machinery is known for advanced and flexible machines. They also have great customer support.

These companies help you keep up with new needs and changes in the market.

Strategic Moves

Top companies move fast to follow new trends. They spend money on new technology and work with other companies to stay strong.

The Indian Paper Manufacturers Association will spend ₹25,000 crore on new technology. This helps lower carbon footprints.

Marigold and Sonoco work together to make recyclable packaging. They want to lower carbon emissions.

Ahlstrom made LamiBak Flex, a flexible and green packaging product.

Billerud made heat-sealable, recyclable paper to replace plastic.

McCormack Family Farms and Smurfit Kappa made biodegradable trays instead of plastic bags.

Notpla uses seaweed-based packaging to replace plastic in the Netherlands.

These actions give you better and greener products to use.

Customer Service

Good customer service helps you use machines without worry. Top companies focus on support, training, and custom solutions.

Aspect | Description |

Technical Support | You get clear manuals and training to use machines well. |

After-Sales Service | Fast repairs and maintenance keep your machines working. |

Customization | You can ask for special changes to fit your business. |

Rokin Machinery also gives strong customer support. You get help with setup, training, and fixing machines. This support helps you get the most from your machines and keeps your business running well.

You see big changes in paper bag making machines in 2025. Automation, smart technology, and eco-friendly designs lead the way. Advanced machines help you make more bags with less waste. If you use these trends, you can grow your business and meet new rules.

Stay ready for new ideas. The future of paper bag making looks bright and full of chances for you to succeed.