Introduction

Plastic bags are everywhere—from grocery shopping to packaging products. But have you ever wondered how these bags are made? The process involves turning raw materials into everyday packaging. In this guide, you will learn how plastic bags are created, from the initial steps of raw material transformation to the final product. We will explore the manufacturing process, machinery used, and the growing trend toward sustainable production.

The Basics of Plastic Bag Manufacturing

Raw Materials for Plastic Bag Production

Plastic bags are primarily made from polyethylene, a polymer derived from natural gas or petroleum. There are two main types of polyethylene used in plastic bag manufacturing: low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is typically used for flexible and transparent bags, while HDPE is stronger and more rigid, often used for heavy-duty bags like trash bags. These polymers are transformed into resin pellets, which are the building blocks for plastic bag production.

Type of Polyethylene | Properties | Common Applications |

Low-Density Polyethylene (LDPE) | Flexible, transparent, tear-resistant | Grocery bags, bread bags, dry cleaning bags |

High-Density Polyethylene (HDPE) | Sturdier, more opaque, resistant to punctures and moisture | Trash bags, heavy-duty retail bags, industrial use |

Essential Machinery in the Process

The manufacturing of plastic bags involves several specialized machines designed for efficiency and precision. The primary machinery includes:

● Extruders: These machines melt the polyethylene resin pellets and form them into a continuous plastic film.

● Blown Film Machines: These machines blow air into the plastic film, expanding it into a tube to create the desired thickness.

● Cutting Machines: These machines cut the continuous plastic film into bags of the required size.

● Sealing Machines: These machines seal the bottom of the bags using heat to form a strong bond.

Each machine plays a critical role in shaping the plastic film and ensuring the final product is durable and functional.

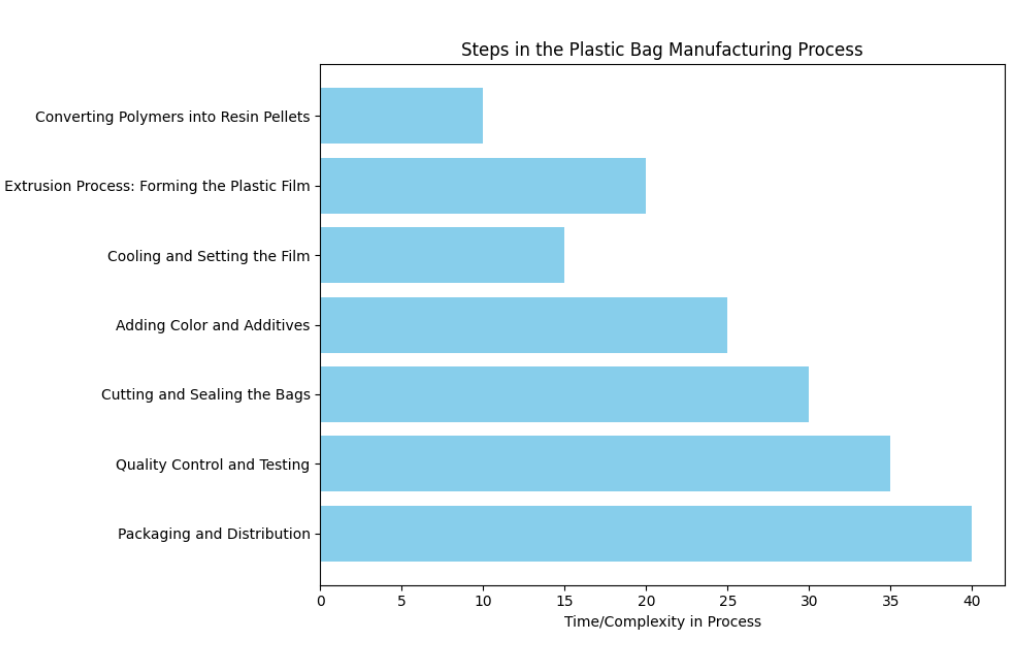

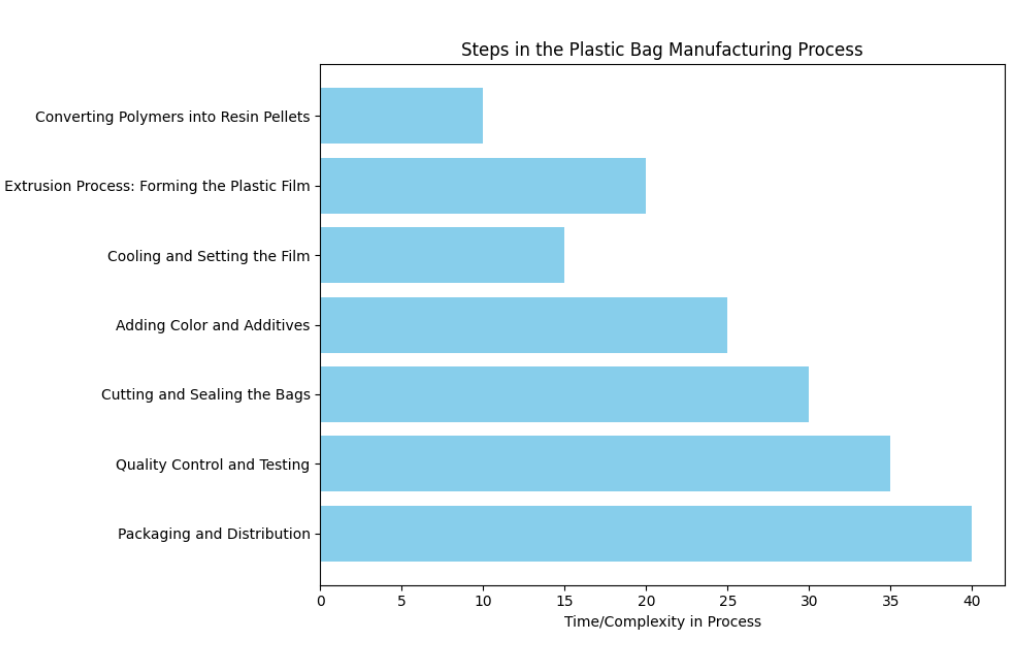

Step-by-Step Process of Making Plastic Bags

Converting Polymers into Resin Pellets

The process begins with raw polymers, typically derived from natural gas or petroleum. These raw materials are subjected to heat and pressure, transforming them into small, cylindrical resin pellets. These pellets serve as the essential building blocks for plastic bag production. The use of resin pellets ensures consistency in the material and simplifies transportation and storage, making them ideal for the next steps in the manufacturing process.

Extrusion Process: Forming the Plastic Film

The resin pellets are then fed into an extruder, where they are heated to high temperatures, melting the plastic. The molten plastic is forced through a circular die, shaping it into a continuous tube of plastic film. This tube is inflated with air, similar to blowing up a balloon, stretching the plastic to the desired thickness. The extrusion process allows for high-volume, consistent production, making it an efficient method for producing plastic film suitable for creating plastic bags.

Cooling and Setting the Film

After the film is formed, it is crucial to cool it rapidly to ensure it maintains its desired strength and thickness. Cooling systems—either air-based or water-based—are used to quickly solidify the plastic as it exits the extruder. This cooling process helps prevent imperfections such as wrinkles or uneven thickness. Rollers are used during cooling to further stretch the plastic, ensuring that the film retains its uniformity and quality, essential for the production of high-quality plastic bags.

Adding Color and Additives

Once the plastic film is cooled, various additives and colorants are mixed in to enhance its properties. Dyes are added to achieve the desired color, while UV stabilizers are incorporated to improve the plastic’s resistance to sunlight and prevent degradation over time. Other additives, like anti-slip agents or anti-static compounds, are also included, depending on the intended application of the plastic bags. These additives improve the functionality of the plastic, making it suitable for a variety of uses, from food packaging to industrial applications.

Cutting and Sealing the Bags

The continuous plastic film is then cut into individual sections of the desired size. Precision cutting machines ensure that each bag is uniform in size. After the film is cut, heat sealing machines are used to seal the bottom of each bag, ensuring a strong and secure closure. This step is essential for the bag’s integrity and load-bearing capacity, as a poorly sealed bag may tear or fail under pressure. Handles or zippers may also be added at this stage, depending on the bag’s design and intended use.

Quality Control and Testing

Quality control is an integral part of the plastic bag manufacturing process. Once the bags are cut and sealed, they undergo rigorous testing to ensure they meet the necessary industry standards. These tests check for:

● Thickness: Ensuring the bag’s thickness is consistent and within required specifications.

● Strength: Testing the bag’s ability to hold weight without tearing or breaking.

● UV Resistance: Checking if the bags can withstand prolonged exposure to sunlight without degrading.

Bags that pass these tests are then approved for distribution, while any bags that fail are discarded or reworked.

Packaging and Distribution

Once the bags have passed quality control, they are stacked, counted, and carefully packaged for shipping. Packaging ensures that the bags remain intact and undamaged during transit. The bags are then ready for distribution to retailers or directly to consumers. This final stage in the production process ensures that the bags are delivered in optimal condition and ready for use in various applications, ranging from retail shopping to industrial storage.

Step | Description |

1. Converting Polymers | Raw polymers like polyethylene are transformed into resin pellets, the building blocks. |

2. Extrusion Process | Resin pellets are melted and extruded into a continuous tube of plastic film. |

3. Cooling and Setting | The plastic film is rapidly cooled to solidify and maintain its desired thickness. |

4. Adding Color and Additives | Dyes and additives are mixed in to enhance functionality, such as UV resistance and color. |

5. Cutting and Sealing | The plastic film is cut into sections, and the bags are sealed at the bottom. |

6. Quality Control | Bags are tested for strength, thickness, and durability to ensure they meet standards. |

7. Packaging and Distribution | Bags are counted, packaged, and prepared for shipment to retailers or consumers. |

Customization in Plastic Bag Manufacturing

Custom Bag Sizes and Features

Plastic bags can be customized in size, shape, and features to meet the specific needs of different industries. For example, a grocery store may require larger bags for carrying bulky items, while a high-end boutique might need smaller, more decorative bags. Manufacturers can adjust the extrusion process to produce bags in various sizes, ensuring they meet the customer’s specific needs.

Personalized Designs and Branding

In addition to size and features, plastic bags can also be customized with logos, designs, or text through flexographic printing. This process allows businesses to personalize the bags with their branding, turning them into an effective marketing tool. Custom bags also help businesses stand out and provide a more professional appearance, contributing to a stronger brand identity.

Sustainability and Eco-friendly Trends in Plastic Bag Production

The Rise of Biodegradable Plastic Bags

As environmental concerns grow, there is increasing demand for biodegradable plastic bags. These bags are made from plant-based materials like corn starch, offering an eco-friendly alternative to traditional plastic bags. While not as durable as their petroleum-based counterparts, biodegradable bags are a more sustainable option for single-use packaging.

Recyclable and Reusable Plastic Bags

There is also a shift towards producing recyclable and reusable plastic bags. These bags are made from higher-quality materials and are designed for multiple uses. Recyclable bags help reduce waste and contribute to a more sustainable environment. Many manufacturers now produce reusable bags that are durable and can be used repeatedly, helping reduce the consumption of single-use plastics.

Reducing Plastic Waste through Recycling

Plastic bag manufacturers are increasingly focused on reducing plastic waste. This is done by recycling offcuts and defective bags, which can be reprocessed and reused in the manufacturing process. By incorporating recycled materials into the production of new bags, manufacturers contribute to reducing the overall environmental impact of plastic waste.

Trend | Description |

Biodegradable Bags | Made from plant-based materials like corn starch, designed to break down faster. |

Recyclable Bags | Bags that can be recycled, reducing waste and improving sustainability. |

Reusable Bags | More durable bags designed for multiple uses, reducing single-use plastic. |

Waste Reduction through Recycling | Efforts to recycle offcuts and defective bags to minimize production waste. |

Conclusion

Plastic bags are a result of a complex and efficient manufacturing process, transforming raw materials into durable products. This process includes steps like polymer conversion, extrusion, and sealing, with a focus on quality control. As sustainability becomes a priority, businesses are offering eco-friendly plastic bag options. Wenzhou Rokin Machinery CO. Ltd. continues to lead in innovative bag production, providing durable and customizable solutions to meet growing consumer and environmental demands.

FAQ

Q: What are plastic bags made of?

A: Plastic bags are primarily made of polyethylene, which comes in forms like LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene). These polymers are derived from petroleum or natural gas.

Q: How are plastic bags made?

A: The process of making plastic bags involves converting raw polymers into resin pellets, then melting and extruding them into plastic film. The film is cooled, cut, sealed, and tested before being packaged for distribution.

Q: What machinery is used in plastic bag manufacturing?

A: Essential machinery includes extruders, blown film machines, cutting machines, and sealing machines. Each plays a crucial role in shaping the plastic and ensuring the bags meet quality standards.

Q: Why are some plastic bags recyclable?

A: Many plastic bags are made from polyethylene, which is recyclable. This helps reduce waste and supports sustainable practices by enabling the recycling of plastic materials into new bags or other products.

Q: Can plastic bags be customized for businesses?

A: Yes, plastic bags can be customized in terms of size, shape, and branding. Manufacturers use special dies and flexographic printing to create bags tailored to specific business needs.

Q: What are the advantages of biodegradable plastic bags?

A: Biodegradable plastic bags are made from plant-based materials like corn starch, breaking down faster than traditional plastic. They offer a more eco-friendly alternative, reducing plastic waste and environmental impact.

Q: How do additives affect plastic bag quality?

A: Additives like UV stabilizers and anti-static agents enhance the plastic bag's durability and resistance to wear. They help improve the bag’s strength, color, and overall functionality, making it suitable for various uses.