You can change how you package things with a

Paper Bag Making Machine. Automation makes work faster and more accurate. This helps you handle more orders for eco-friendly packaging. A new market report says the market will grow a lot. It may double by 2032.

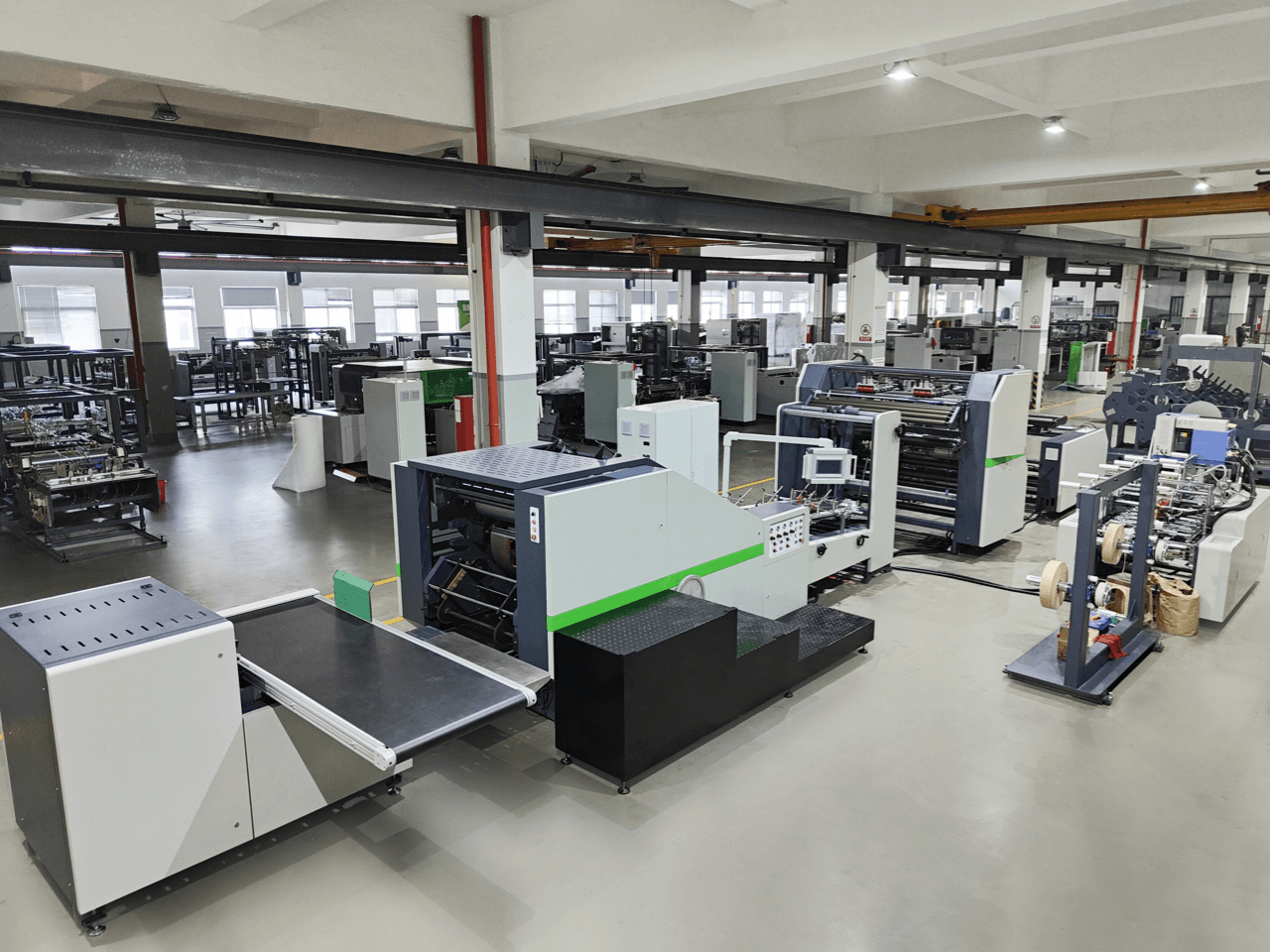

Rokin Machinery gives smart solutions for many types of businesses. The

machine’s technology helps you work better and save money on workers.

Benefit | Description |

Enhanced Efficiency and Precision | Automated machines work faster and make fewer mistakes. This is important for making lots of bags. |

Reduced Labor Costs | Automation means you need fewer workers. This lowers costs and mistakes. |

Focus on Sustainability | New trends want machines to use less energy and green materials. This matches what customers want. |

Key Takeaways

A Paper Bag Making Machine helps businesses work faster. It makes bags by itself. Companies can make up to 30,000 bags every hour.

This machine lowers labor costs a lot. It needs fewer workers. It also makes fewer mistakes. This helps companies earn more money.

The machine uses biodegradable materials. This helps the environment. Businesses can meet eco-friendly packaging needs. They can also get more customers.

Companies can choose different bag types and sizes. They can add logos and designs. This helps people notice their brand.

Buying a Paper Bag Making Machine shows your business cares about the planet. It attracts people who want to help the environment.

Packaging Challenges

Demand for Sustainability

There is more pressure to use eco-friendly packaging now. Most people want to help the planet, so they pick products with green packaging. Using sustainable packaging is needed today, not just popular. If you do not change, you might lose customers to other companies with better options.

The EU has new rules about plastic packaging. These rules are changing how companies package things. Old ways will not work for future laws or what customers want.

Many businesses are moving from plastic to paper packaging. They do this because of new rules and what customers ask for. A Paper Bag Making Machine helps you follow these rules and shows you care about the environment.

Labor and Cost Pressures

Labor costs are going up. It is harder to find skilled workers now. Packaging lines need many workers, so costs get higher.

Here is a table that lists common labor and cost problems:

Evidence Type | Description |

Labor Inefficiencies | Bad workflows and poor training slow down work and add hidden costs. |

Equipment Downtime | Machines breaking down costs a lot because of repairs and delays. |

Labor Shortages and Wage Increases | Needing more workers when there are not enough makes wages go up. |

Automating your packaging process helps with these problems. You can save money and keep your business working well.

Quality and Consistency Issues

Manual packaging can cause mistakes. Even small errors can lead to big problems like broken products or wasted materials.

People can make mistakes that ruin packaging.

Bad seals can happen if workers mess up.

Wrong labels can be put on if details are missed.

Weak closures can break during shipping.

You want every package to look good and keep products safe. When packages are always the same, customers trust you more. Automated machines help you avoid these problems and give good results every time.

Paper Bag Making Machine Solutions

Automation and Speed

A Paper Bag Making Machine can change how you pack things. It puts many steps together into one easy process. You put in rolls of paper, and the machine does the rest. It feeds, cuts, folds, glues, and stacks the bags for you. Some machines can even print your logo or design on each bag.

Here is how the machine helps make bags faster:

Function | Description |

Material Feeding | You load kraft or recycled paper into the machine. |

Printing (Optional) | You can add your brand or design with built-in printers. |

Cutting and Folding | Sharp blades cut the paper, and folding shapes the bag. |

Gluing and Sealing | Special glue holds the seams and bottom tight for strong bags. |

Output | Finished bags are stacked and ready to use or pack. |

The machine makes bags much faster than people can by hand. It can make between 2,500 and 30,000 bags every hour. People working by hand can only make about 50 to 60 bags in an hour. This big difference helps you fill large orders and meet short deadlines.

Production Method | Speed (pieces per hour) |

Fully Automatic Machines | 2,500 - 30,000 |

Manual Methods | 50 - 60 |

Automatic machines help you work up to three times faster than old ways. You can spend 70% less on workers and waste less than 0.5% of materials. Some companies have saved over 60% on labor after using these machines. The machine keeps running without stopping for new paper rolls, so you make up to 30% more bags.

Tip: If you want your business to grow, a Paper Bag Making Machine lets you make more bags with fewer workers.

Consistent Quality

You want every bag to look nice and work well. A Paper Bag Making Machine uses smart tools to keep quality high. It checks how thick the paper is, keeps the right tension, and uses sharp blades to cut. You can set the machine for your paper type and size, so every bag matches.

Mechanism/Feature | Description |

Adaptive Feed Mechanisms | The machine senses paper thickness and adjusts for smooth work. |

Calibration Settings | You enter paper details, and the machine changes settings for best results. |

Tension Control | It keeps the paper tight so bags do not tear or get crooked. |

Versatile Cutting Blades | The machine changes blade speed and pressure for clean cuts. |

Adhesive Application | It uses just the right amount of glue for strong seams. |

Operator Training | Workers learn to adjust settings for top results. |

Vendor Consistency | Using good paper from trusted sellers keeps bag quality steady. |

Smart sensors and controls mean fewer mistakes and less wasted paper. You can trust every bag will be good, which makes customers happy.

Versatility and Customization

A Paper Bag Making Machine can make many kinds of bags. You can pick different sizes, shapes, and handle types. The machine can make flat bottom, square bottom, and V-bottom bags. You can add twisted or flat handles and print your logo or design.

Bag Type | Features | Customization Options |

Flat Bottom Bags | Makes many sizes quickly | You can change the size |

Square Bottom Bags | Strong bags for heavy things | Folds and glues bags automatically |

V-Bottom Bags | Flexible for many uses | Pick handle styles and printing options |

Pick custom sizes for each bag type

Add handles if you want

Use built-in printing features

Advanced automation makes work faster

You can set up the machine for your business. Bakeries can make food-safe bags. Stores can make shopping bags with their logo. The machine works with eco-friendly materials, so you can give customers green packaging.

Note: New Paper Bag Making Machines use smart tech, work fast, and save energy. You get more choices and better bags for your business.

Operational Process

Workflow Steps

You can turn a simple paper roll into a finished bag by following a clear process. Each step uses advanced technology to make sure every bag meets your standards. Here is how the workflow usually goes:

Raw Material Selection

You choose the right type of paper for your bags.

Paper Roll Loading

You load the paper roll onto the machine.

Paper Unwinding and Tension Control

The machine unwinds the paper and keeps the tension steady.

Printing and Customization

You can add logos or designs during this step.

Edge Glue Application

Glue goes on the edges to hold the bag together.

Bag Tube Formation

The machine folds the paper into a tube shape.

Bag Cutting and Separation

The machine cuts each bag to the right size and separates them.

Bottom Folding and Gluing

The bottom of the bag gets folded and glued for strength.

Each step helps you get strong, neat, and ready-to-use paper bags.

Key Features

Feature | Description |

High Production Speed | You can meet large orders quickly, which keeps your customers happy. |

Automated Production Process | The machine does most tasks for you, so you get more bags with less work. |

Durability and Reliability | Strong parts let the machine run for long hours without problems. |

Cost-effectiveness | Automation saves money by using less labor and reducing wasted materials. |

These features help you keep up with busy times and big orders.

User-Friendly Interface

You do not need special skills to run a Paper Bag Making Machine. The controls are simple and easy to understand. You can change bag sizes or designs with just a few taps. This design helps you train new workers quickly. You spend less time fixing mistakes and more time making quality bags. The easy interface keeps your workflow smooth and your production steady.

Eco-Friendly Benefits

Biodegradable Materials

You help the earth when you pick paper bags made from biodegradable materials. These bags break down on their own, so they do not hurt nature for a long time like plastic bags. Most paper bag making machines use materials that are good for the planet. Some common choices are kraft paper and recycled paper. Kraft paper comes from wood pulp and has strong fibers. It is tough and breaks down fast in nature. Recycled paper uses old paper, which saves trees and cuts down on trash. Both choices let you give packaging that makes customers feel proud to use it.

Using biodegradable paper bags shows your customers you care about the earth. This helps lower pollution and supports a cleaner future.

Supporting Sustainability Goals

A paper bag making machine helps your business reach its sustainability goals in many ways. Fast machines let you fill big orders quickly, so you use less energy for each bag. Smart tech helps you waste fewer materials when making bags. High output lets you meet the growing need for eco-friendly packaging. Paper bags do more than just break down. Many can be recycled, which helps keep materials in use. If you use paper from forests that are managed well, you also make less pollution than plastic bags.

Aspect | Paper Bags | Plastic Bags |

Biodegradability | Biodegradable and compostable | Resistant to breaking down |

Environmental Practices | Depends on good forestry and water use | Adds to long-lasting pollution |

Recycling | Compostable, but needs the right disposal | Not recycled much in real life |

More people want eco-friendly packaging every year. The food and drink industry is leading this change because customers want easy options and care about the planet. Companies now use greener packaging to match what buyers want. New rules also make businesses switch to better choices.

Picking a paper bag making machine helps your business lead the way to a greener world. You meet what customers want and help protect the earth at the same time.

A Paper Bag Making Machine helps you fix packaging problems. Automation lets you use less energy. You can make more bags each day. You also waste less material. Many businesses say they work better with automated machines. Their products are higher quality. You can make bags in different styles and sizes. This machine helps your brand look good. It also gives customers the eco-friendly packaging they want. Picking smart machines like Rokin Machinery’s helps your business grow. You can stay ahead of other companies.