Introduction

As sustainability becomes a top priority, businesses are increasingly seeking eco-friendly packaging options. Kraft paper packaging has emerged as a leading solution, offering strength and environmental benefits. Made from wood pulp, it combines durability with biodegradability, making it ideal for a wide range of applications.

In this article, we'll explore everything you need to know about kraft paper packaging. From its origins and benefits to its diverse uses across industries, we'll cover how kraft paper continues to evolve in the world of sustainable packaging.

What is Kraft Paper Packaging?

Definition of Kraft Paper

Kraft paper is a strong, durable type of paper made from wood pulp through a special chemical pulping process known as the “kraft process.” The word "kraft" is derived from the German word for “strength,” reflecting the material’s exceptional durability. This type of paper is most commonly recognized by its brown color, although it can also be bleached or dyed for specific uses. Its strength and versatility make it a go-to material for packaging in various industries, including food, retail, and industrial sectors.

Composition of Kraft Paper

Kraft paper is made primarily from wood pulp, a renewable resource that ensures the material is both sturdy and eco-friendly. The kraft process involves breaking down wood chips with a chemical solution of sodium hydroxide and sodium sulfide, which separates the cellulose fibers from the lignin. The resulting paper retains the natural strength of the fibers, making it resistant to tearing and capable of handling substantial weight, making it ideal for applications like packaging, bags, boxes, and more.

Historical Background

The origins of kraft paper date back to the 1880s when Carl F. Dahl, a German inventor, developed the kraft process. This process allowed for stronger paper, ideal for packaging and other industrial applications. Initially used as a packaging material, kraft paper has evolved significantly over the years, and today it is prized not only for its strength but also for its eco-friendly properties. Its versatility and sustainable nature have made it a popular choice in modern packaging solutions.

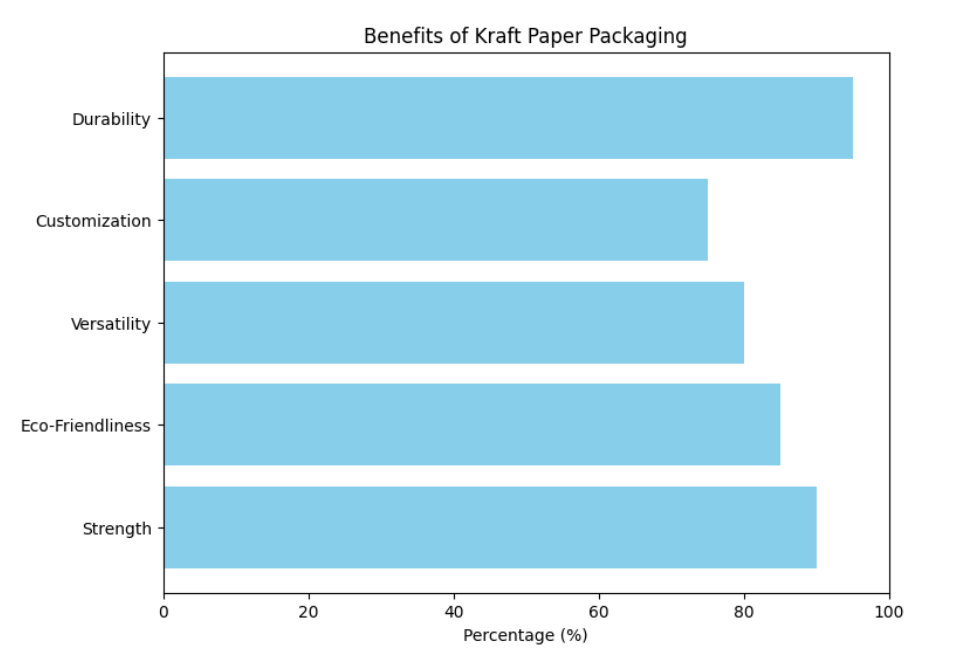

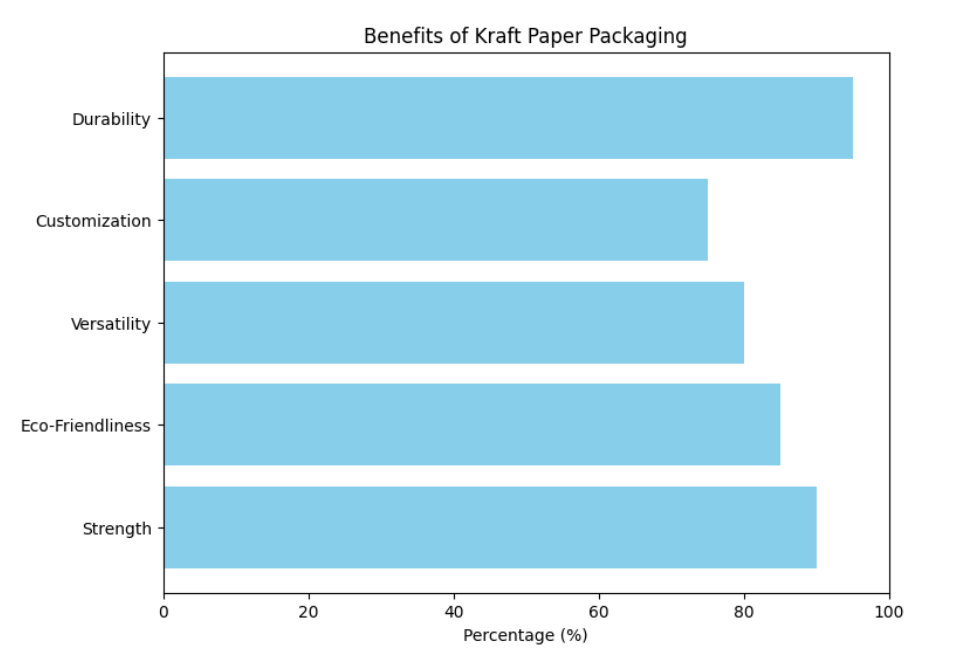

Benefits of Using Kraft Paper for Packaging

Strength and Durability

One of the standout qualities of kraft paper is its exceptional strength and tear resistance. The longer and stronger cellulose fibers in kraft paper make it more durable than regular paper. This durability makes kraft paper ideal for packaging applications that require protection and load-bearing capabilities. Whether used for heavy-duty shipping boxes or grocery bags, kraft paper can handle substantial weight and pressure without tearing, reducing the likelihood of damage during transport.

Eco-Friendliness

Kraft paper offers significant environmental benefits that make it a top choice for sustainable packaging. It is biodegradable and recyclable, which means it can break down naturally without leaving harmful residues. Unlike plastic, kraft paper’s environmental impact is minimal, as it doesn’t contribute to pollution or landfill waste. Kraft paper can be recycled up to seven times before the fibers lose their strength, ensuring that it remains a sustainable option for businesses and consumers. The growing demand for green packaging solutions makes kraft paper an attractive alternative to plastic and other non-biodegradable materials.

Versatility and Customization

The versatility of kraft paper is another major benefit. It can be used across various packaging applications, from food packaging to retail bags and industrial boxes. Kraft paper can also be easily customized through printing, coloring, and special coatings to meet specific branding needs. Whether you're looking for a rustic, natural appearance or a more polished look, kraft paper can adapt to different styles, making it a great option for businesses in need of customized packaging. Additionally, its natural look provides an artisanal, organic aesthetic that appeals to consumers looking for eco-conscious products.

Types of Kraft Paper Packaging Materials

Coated vs. Uncoated Kraft Paper

Kraft paper comes in two primary types: coated and uncoated. Coated kraft paper is treated with a layer of polyethylene (PE) or other materials to enhance its resistance to moisture, grease, and other contaminants. This makes it ideal for food packaging, especially for items like takeout containers and snack bags. On the other hand, uncoated kraft paper retains its natural texture and is more breathable, which makes it suitable for applications like agricultural or clothing packaging, where air circulation is important.

Recycled vs. Virgin Kraft Paper

Another important distinction is between recycled and virgin kraft paper. Virgin kraft paper is made from fresh wood pulp, offering superior strength, consistency, and durability. It’s particularly useful for heavy-duty packaging applications, such as shipping materials or premium packaging. On the other hand, recycled kraft paper is made from post-consumer or post-industrial waste, making it a more sustainable and eco-friendly option. Recycled kraft paper still maintains much of the durability and strength of virgin kraft paper, making it an excellent choice for businesses looking to minimize their environmental impact.

Specialized Kraft Paper Types

There are also specialized kraft paper types designed for specific applications. Water-resistant kraft paper is used for packaging that needs protection from moisture, such as outdoor products. Grease-proof kraft paper is commonly used in the food industry to prevent oils and fats from leaking through packaging, making it ideal for fast food and bakery items. Machine-glazed kraft paper offers a smooth surface that enhances printability, making it suitable for products requiring a more polished look.

Type of Kraft Paper | Key Features | Common Applications |

Coated Kraft Paper | Moisture and grease resistance | Food packaging, takeout containers, snack bags |

Uncoated Kraft Paper | Natural texture, breathable | Agricultural packaging, clothing packaging |

Recycled Kraft Paper | Made from post-consumer waste | General goods packaging, eco-friendly packaging |

Virgin Kraft Paper | Made from fresh wood pulp, high strength | Heavy-duty packaging, shipping, machinery protection |

Specialized Kraft Paper | Water-resistant, grease-proof, machine-glazed | Food industry, outdoor packaging, premium product packaging |

Industry Applications of Kraft Paper Packaging

Food Industry

In the food industry, kraft paper is essential for packaging dry foods, baked goods, snacks, and more. Its natural resistance to moisture and grease makes it a great choice for food containers, such as takeout bags and food wraps. Many types of kraft paper are food-grade certified, ensuring they meet health and safety regulations for direct contact with food. Additionally, kraft paper is preferred because it helps maintain the freshness of food, preventing spoilage and contamination.

Retail Industry

Kraft paper is widely used in the retail industry for packaging various products. From shopping bags to gift boxes, kraft paper provides a natural, rustic look that appeals to environmentally-conscious consumers. Many retail businesses choose kraft paper because of its eco-friendly appeal and its ability to convey authenticity and sustainability. Custom-printed kraft paper bags and boxes help businesses build brand identity and strengthen their market presence while maintaining a focus on environmental responsibility.

Industrial Applications

In industrial applications, kraft paper is often used to package heavy-duty products, such as machinery or electronics, that require secure and durable protection. Its strength and tear resistance make it ideal for wrapping large or fragile items that need to withstand rough handling and transit. Kraft paper is also used for protective wraps, ensuring goods are safe during shipping and handling.

How Kraft Paper Packaging Contributes to Brand Image and Consumer Perception

Authenticity and Sustainability

The use of kraft paper packaging helps businesses create an authentic and sustainable brand image. Kraft paper’s natural look and eco-friendly qualities resonate with consumers who prioritize sustainability. By using kraft paper, businesses communicate a commitment to environmental responsibility, which strengthens their brand reputation and builds consumer trust.

Consumer Preferences

As more consumers prioritize sustainability, the demand for eco-friendly packaging continues to grow. Studies show that many consumers are willing to pay a premium for products that use biodegradable, recyclable, or sustainably sourced materials. Brands that use kraft paper packaging can attract environmentally-conscious customers and increase loyalty among existing ones. As consumer awareness of environmental issues rises, businesses that embrace sustainable packaging solutions are likely to stand out in the market.

Trend | Impact on Consumer Behavior |

Growing demand for sustainability | Consumers increasingly choose eco-friendly packaging |

Willingness to pay more for sustainable products | 72% of consumers prefer to buy products with sustainable packaging |

Preference for brands with strong environmental commitments | Strengthens brand loyalty and appeals to eco-conscious buyers |

How to Choose the Right Kraft Paper for Your Packaging Needs

Determine the Application Type

To select the right kraft paper, businesses need to consider the application type. Different products require different strengths and finishes. For example, virgin kraft paper is recommended for heavy-duty packaging, while coated kraft paper is better suited for food products that need moisture or grease resistance.

Consider Durability and Weight

When choosing kraft paper, businesses must also take into account the durability and weight needed for their packaging. Thicker, heavier kraft paper offers more strength, making it suitable for items that require secure packaging. Lighter kraft paper is ideal for less fragile items or for applications that don’t require as much strength.

Explore Customization Options

Kraft paper is highly customizable to meet branding requirements. Businesses can opt for custom printing, unique colors, or even embossing to create a distinctive packaging solution. Additionally, businesses can add special features such as handles, windows, and coatings to enhance the overall appeal and functionality of their packaging.

The Future of Kraft Paper Packaging

Trends in Sustainable Packaging

As the demand for sustainable packaging continues to rise, the future of kraft paper looks bright. Consumers are increasingly looking for eco-friendly options, and kraft paper is at the forefront of this trend. With growing concerns about plastic waste and environmental degradation, kraft paper offers an alternative that is biodegradable, recyclable, and produced with minimal environmental impact.

Innovations in Kraft Paper Packaging

Innovations in kraft paper technology are expanding its capabilities. New advancements in printing techniques, grease resistance, and moisture protection are making kraft paper even more versatile. Additionally, the development of compostable kraft paper is pushing the material even further toward complete sustainability. As these innovations continue, kraft paper is expected to remain a leading option for businesses seeking sustainable packaging solutions.

Conclusion

Kraft paper packaging is a sustainable solution that helps businesses reduce their environmental footprint while maintaining durability. Its versatility and eco-friendliness make it ideal for various industries, from food packaging to retail. As the demand for sustainable options grows, kraft paper continues to shape the future of packaging. By switching to kraft paper, businesses can enhance their brand image and appeal to eco-conscious consumers.

For companies like Wenzhou Rokin Machinery CO. Ltd., providing kraft paper packaging solutions helps promote both sustainability and product strength.

FAQ

Q: What is Kraft Paper packaging?

A: Kraft paper packaging is a durable and eco-friendly packaging material made from wood pulp through a chemical process called the kraft process. It is known for its strength and biodegradability, making it ideal for various industries.

Q: Why is Kraft Paper considered eco-friendly?

A: Kraft paper is biodegradable, recyclable, and made from renewable resources like wood pulp. It breaks down naturally and can be recycled multiple times, reducing environmental impact compared to plastic packaging.

Q: How is Kraft Paper used in packaging?

A: Kraft paper is used in various packaging forms, including bags, boxes, wraps, and food containers. Its strength and customization options make it suitable for food, retail, and industrial applications.

Q: What are the advantages of using Kraft Paper for packaging?

A: Kraft paper offers high durability, tear resistance, and eco-friendliness. It also provides customization options, making it a versatile choice for packaging needs across different industries.

Q: Is Kraft Paper packaging cost-effective?

A: Yes, Kraft paper is a cost-effective option for businesses, especially compared to other materials like plastic. Its affordability, combined with its environmental benefits, makes it an attractive choice for sustainable packaging.