Smart technology has changed how people use paper bag making machines. Automation makes work easier and faster. Simple controls help you save money.

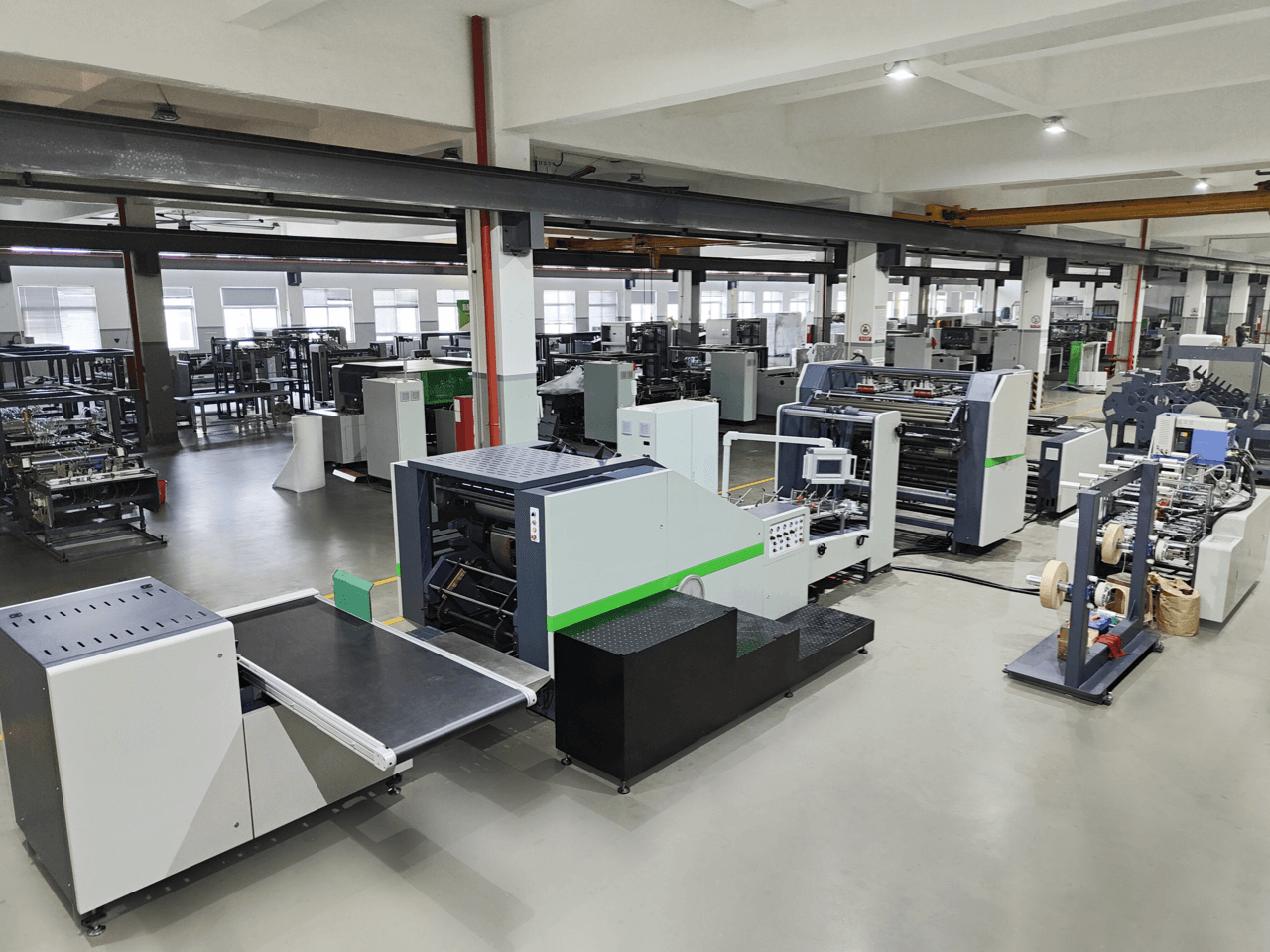

Rokin Machinery is a leader in this field. Their machines use less energy and make less waste. They also help you spend less money.

Aspect | Percentage | Description |

Energy savings | ~20% | Each bag needs less power to make |

Waste reduction | Up to 25% | Fewer materials are wasted when making bags |

Defects reduction | Below 2% | Quality checks keep products the same |

You can help the environment and grow your business with these smart machines.

Key Takeaways

Smart technology helps paper bag machines work by themselves. This makes making bags faster and easier. Real-time monitoring finds problems fast and helps fix them quickly. This keeps the bags good and stops the machine from stopping for long. Adaptive production lets the machine change bag sizes and styles fast. This helps meet many customer needs. Using less energy and materials saves money. It also helps the environment. User-friendly designs and remote alerts make the machine easy to use. This means workers learn faster and make fewer mistakes.

Smart Features of Paper Bag Making Machine

Automated Controls

The automatic paper bag making machine has smart controls. These controls make your job easier and more exact. You use a touch screen to run the machine. You can control each step with just a few taps. This makes it simple to set up and change settings. The servo-driven system keeps bag sizes the same. It also helps stop mistakes. The machine does most jobs by itself, so you do not have to worry about human errors.

Here is a table with some key automated control features:

Feature | Description |

Fully Automatic | Automates the whole process of making paper bags with handles. |

Touch Screen Control | Has an easy-to-use touch screen for simple operation. |

Servo Motor Technology | Uses accurate servo motors for steady and quick work. |

Automatic Tension Control | Changes tension and fixes problems during work. |

In-line Handle Pasting | Puts handles on bags in one step, so you do not need to do it by hand. |

The machine also glues, folds, cuts, forms the bottom, and collects bags in one go. This makes your work faster and saves time and effort.

Tip: Automated controls help you make more bags quickly. They also keep every bag the same size and shape.

Real-Time Monitoring

Real-time monitoring lets you see the whole process as it happens. The machine uses sensors and a touch screen to show you what is going on. If there is a problem, the system tells you right away. You can fix issues before they stop your work.

Modern machines use IoT and sensors to watch how things are running. These tools help you keep the machine working well and avoid stops. You can also get help fast with remote diagnostics if you need it.

Evidence | Description |

Integrated Sensors | Watch production in real-time and help with quick repairs. |

Predictive Maintenance | Warns you about problems before they cause a stop. |

Remote Diagnostics | Lets you get help fast, so you lose less time. |

Real-time monitoring helps you keep quality high. The machine checks each bag for problems and removes bad ones. This keeps your products good and your customers happy.

Adaptive Production

The automatic paper bag making machine can change to fit your needs. You can switch settings fast to make different bag sizes or use new materials. The controls are easy, even if you are new to machines.

Here are some adaptive production features you will like:

Makes up to 200 bags each minute.

Switches quickly between bag sizes and types.

Can use many paper thicknesses and bag styles.

Lets you add your own designs and logos.

Has touchscreen and PLC controls for easy use.

The machine is strong and works well for big jobs. You can trust it for long hours and big orders. The modular design lets you change the machine for different bag types, so you have more choices in your work.

Note: Adaptive production features help you meet new customer needs and keep your business strong.

The paper bag machine from Rokin Machinery uses the latest technology and smart features. You get a smooth process, strong quality checks, and a machine that grows with your business.

Efficiency of Paper Bag Machine

Fast Production

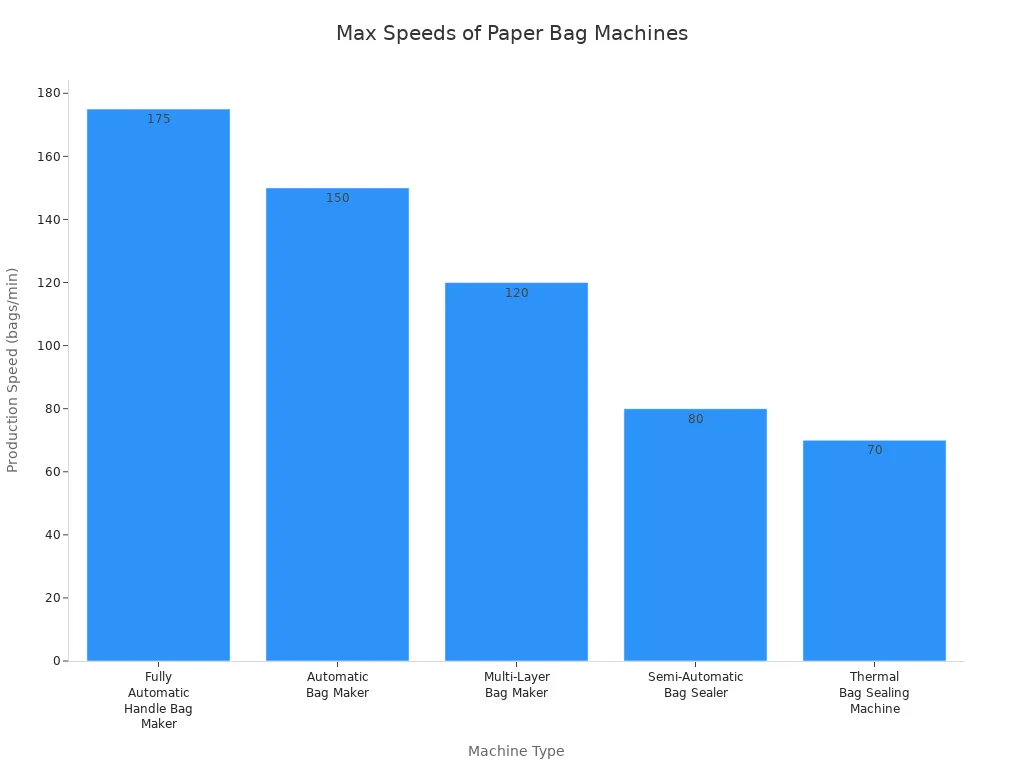

You want your business to keep up with orders. A modern paper bag machine helps you do this. These machines can make up to 200 bags each minute. This lets you finish big orders fast and keep customers happy. When you look at other machines, this speed is much better.

Machine Type | Production Speed (bags/min) |

Fully Automatic Handle Bag Maker | 175 |

Automatic Bag Maker | 150 |

Multi-Layer Bag Maker | 120 |

Semi-Automatic Bag Sealer | 80 |

Thermal Bag Sealing Machine | 70 |

A fast paper bag machine changes how you work. You can finish jobs sooner and take more orders. You also save money because fewer workers are needed. Here are some ways fast machines help:

One person can run many machines, so you pay less for workers.

You can finish big orders fast and earn more money.

You do not need to pay for extra hours or extra shifts.

You use your time and money better and waste less.

Tip: Fast machines help your business grow without hiring more people.

Your work becomes smoother and more steady. You get the same amount of bags each time and have fewer slowdowns. This helps you keep your promises to customers and makes your business look good.

Reduced Waste

A smart paper bag machine does more than work fast. It also helps you use materials better. The machine uses special controls to cut paper very carefully. This means you waste less paper when making bags. You also help the earth by using less power and making less trash.

Here are some ways the machine helps you waste less:

It uses motors that save energy and lower power bills.

The design uses all parts of the paper roll.

You can use recycled and biodegradable paper to help the planet.

The machine works with many paper thicknesses, so you do not throw away extra paper.

You can also follow new packaging rules. Many places want to stop plastic waste. They ask companies to use packaging that is better for the earth. A paper bag machine helps you follow these rules and keeps your business safe.

Note: Using less paper and energy saves money and helps the earth.

Many people care about eco-friendly packaging. They want products that do not hurt nature. Paper bags are a good choice because they break down and can be recycled. Making paper bags with these machines helps the earth and lowers pollution.

Eco-friendly packaging means less trash in landfills and oceans.

Paper bags break down on their own and can be used again.

Using green materials helps you meet what customers and the law want.

Quality checks are also important for less waste. The machine looks at each bag as it is made. If there is a problem, it takes out the bad bag right away. This keeps your bags good and stops waste before it starts.

Quality checks help you make sure every bag is good.

You can see how a paper bag machine makes your work better. You get bags faster, waste less, and have better quality. You also help the earth and follow important rules. This makes your business stronger and more trusted.

User-Friendly Design

Intuitive Interface

A paper bag machine with an easy-to-use interface makes your job simple. The touch screen and PLC controls are not hard to use. You do not need a lot of time to learn the machine. New workers can start fast and feel sure about their work.

The interface gives clear steps and has many languages. You can change the language quickly, so you follow safety rules in your area.

You can change bag sizes and designs with a few taps. This keeps your work moving and helps stop mistakes.

Operators can use all the options without special skills. You do not need to be an expert to run the paper bag machine.

The easy design means less time spent on training. Your team can focus on making good bags instead of learning hard systems.

You will see fewer mistakes and get more done. The machine helps you make lots of bags and keep quality high.

Tip: A simple interface helps you make fewer mistakes and keeps your work going well.

Remote Alerts

Remote alerts help you feel calm when using a paper bag machine. You can check the machine from anywhere with your phone or computer. The system sends alerts right away if something needs your help.

The remote system watches important things like temperature and airflow. You get updates fast if something changes.

You get alerts by email or text. This helps you act quickly and stop problems before they slow you down.

The system works all the time and keeps your data safe. You can trust it to keep your paper bag machine working well.

Aspect | Description |

Remote Alerts | Technicians get alerts about problems before they stop work, so they can fix things early. |

Data Monitoring | Important data like temperature and pressure is always checked to find problems. |

Early Warning System | Automatic messages are sent when something is not normal, so you have less downtime. |

You can fix problems faster and have less downtime. Experts can help you from far away, so your work does not stop. This system helps you keep quality high and makes sure you always get good results.

Note: Remote alerts help you get ready for problems and keep your paper bag machine working well.

Competitive Edge

Customization

You want your paper bags to be special. Rokin Machinery gives you lots of ways to change your bags. You can pick the size and style you want. You can add your own logo or design. The machine makes shopping bags, food bags, and gift bags. You can choose twisted or flat handles. This helps you give customers what they need.

Here is a quick look at what you can change:

Customization Option | Description |

Adjustable Bag Sizes | Make bags in many sizes for different uses. |

Printing Options | Add custom designs, logos, or patterns with advanced printing tech. |

Different Bag Styles | Create shopping, food, or gift bags with various handle types. |

You can change your bags fast when the market changes. If someone wants a new size or style, you can set up the machine in minutes. This helps you do better than others who cannot change quickly. You can use special features like handle application and custom printing. These help you match your brand or your client’s needs.

Tip: Customization helps you get more customers by giving them what they want.

Scalability

When your business gets bigger, you need machines that keep up. Rokin Machinery has many models like RKHF-220T, RKHF-330T, RKHF-450T, and RKHF-460T. Each model works for different business sizes and bag needs. Small shops can start with a basic model. Big factories can use advanced models for faster work.

Model | Max Speed (bags/min) | Bag Width Range (mm) | Best For |

RKHF-220T | Up to 120 | 80–220 | Small businesses, startups |

RKHF-330T | Up to 200 | 130–330 | Medium to large businesses |

RKHF-450T | Up to 200 | 200–450 | High-volume, large factories |

RKHF-460T | Up to 200 | 260–460 | Large-scale, custom projects |

You can upgrade your machine when you get more orders. You do not need to buy a whole new system. The machines work fast and use automation to save time and work. This means you can handle more orders without extra effort.

Upgrade models without changing everything.

High speeds help you make more bags.

Automation works for small and big businesses.

Rokin Machinery’s smart features and flexible models help you stay ahead. You can grow your business and meet new challenges with confidence.

Smart technology helps you a lot when using a paper bag making machine. You can make bags faster and waste less material. The bags also turn out better. The table below shows how these machines help your business:

Benefit | Description |

Automation | Makes work easier and helps you make bags faster. |

Real-time Monitoring | Lets you fix problems quickly for better results. |

IoT and AI Integration | Makes the machine work better and lets you make special bags. |

Environmental Impact | Helps you use less energy and make less waste. |

You also spend less money and can help more customers. Here are some ways things get better:

Advantage | Description |

Efficient production | One machine does the job of many people, so you pay less for workers. |

Precision technology | Smart controls keep waste very low, under 1%. |

Functional adaptation | Works with many materials, so your packaging is better for the earth. |

You can count on Rokin Machinery to help your business grow with smart and strong machines.