The ROKIN Compact Cardboard Slitting Machine is a space-saving, energy-efficient solution designed for recycling plants and waste paper processing facilities. With its integrated compact structure, durable cutting system, and automatic dust removal unit, it efficiently converts recycled or compressed cardboard into reusable strips or sheets. Engineered for stable performance, low maintenance, and environmental compliance, this model is ideal for sustainable production and continuous operation in recycling environments.

Key Features – Compact & Designed for Recycling

Compact One-Piece Structure

Built with a small footprint and integrated frame, the machine fits perfectly in recycling workshops or warehouses while maintaining cutting precision and stability.

Energy-Efficient Motor System

Uses a high-efficiency drive motor to reduce power consumption and operating costs. Simple maintenance and durable components ensure 24-hour continuous operation.

Built-In Dust and Waste Collection

Equipped with an integrated dust extraction and scrap collection system, keeping the work area clean and compliant with environmental standards.

Reinforced Wear-Resistant Blades

The cutting blades are made from high-grade alloy steel, capable of handling recycled, compressed, and uneven cardboard without tearing or jamming.

Applications – Compact Solution for Recycling Operations

Recycling Plants – Processes used cardboard, corrugated waste, and recycled paperboard into reusable sheet materials.

Waste Management Facilities – Ideal for compact installation in material recovery stations with limited space.

Packaging Recovery Lines – Converts packaging waste into uniform strips for reprocessing or baling.

Paper Reuse Workshops – Supports circular production and sustainable material handling.

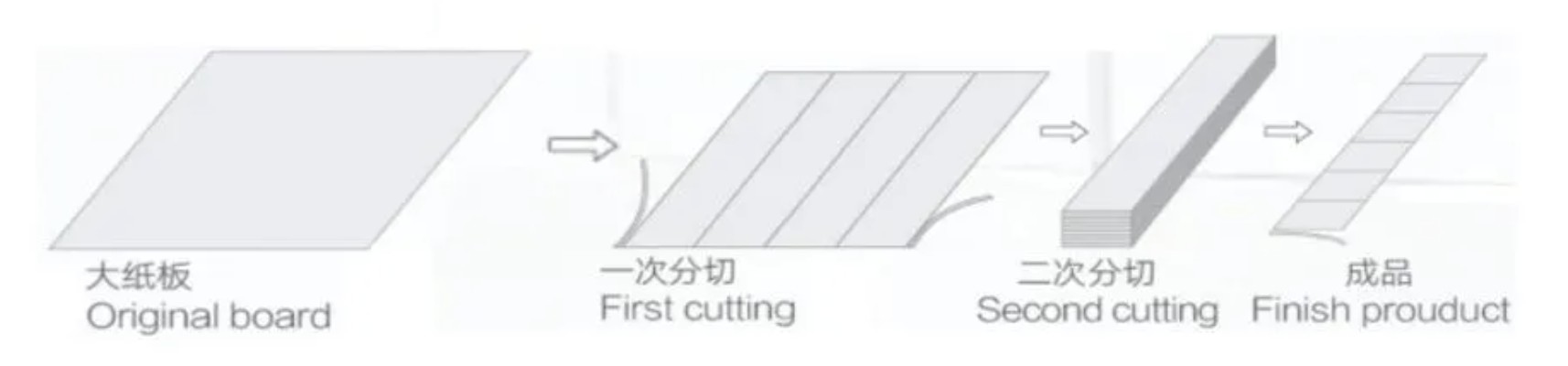

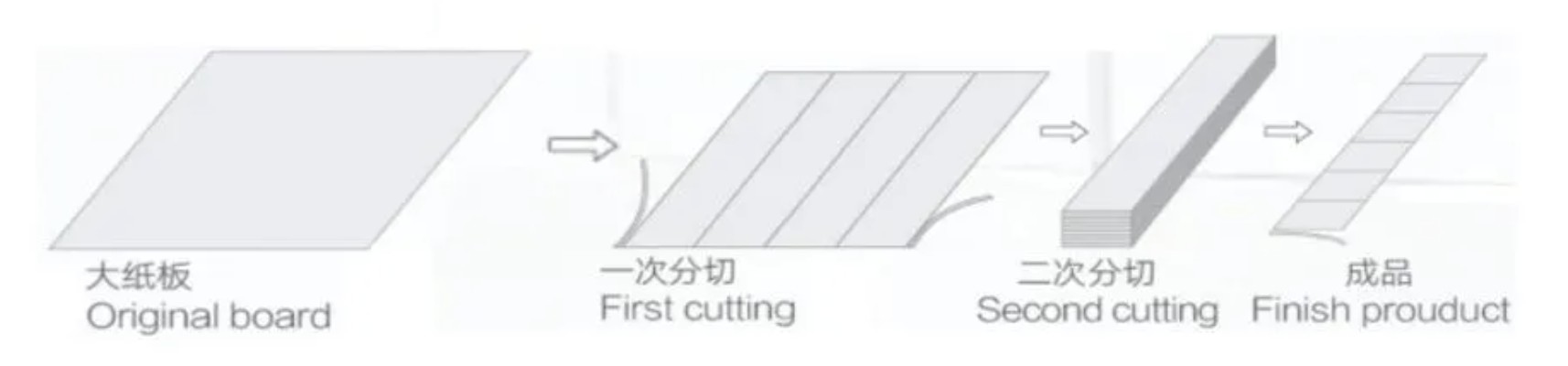

Technical Process

Feeding — Recycled or waste cardboard is fed into the machine.

Slitting (Longitudinal Cutting) — The board is cut into narrow strips according to preset width.

Cross-Cutting (Optional) — Strips can be trimmed to specific lengths for reuse or recycling.

Dust Collection & Output — Dust and scrap are automatically removed, and clean strips are discharged for stacking or baling.

Technical Parameters

| Item | Specification |

| Capacity of the Board Feeder | Max. 30 Sheets / Min |

| Capacity of the Strip Feeder | Max. 120 m / Min |

| Machine Power | 11 kW / 50Hz / 3 Phase |

| Machine Dimensions | L11000 × W6700 × H2200 mm |

FAQ

Q1: What makes the ROKIN Compact Cardboard Slitting Machine suitable for recycling plants?

A1: It’s designed with a compact, space-saving frame that fits easily into recycling facilities. Despite its small footprint, it delivers stable performance, precise cutting, and efficient dust collection—ideal for recycling environments.

Q2: Can this machine handle recycled or uneven cardboard materials?

A2: Yes. The reinforced wear-resistant alloy blades can process recycled, compressed, or irregular cardboard without tearing or jamming, ensuring consistent cutting quality.

Q3: How does the dust and waste collection system work?

A3: The machine integrates a built-in dust extraction and scrap collection system that continuously removes fine particles and waste during cutting, maintaining a clean and eco-friendly workspace.

Q4: Is the machine energy efficient for continuous operation?

A4: Absolutely. The high-efficiency motor system minimizes power consumption while allowing 24-hour continuous operation with low maintenance needs, reducing overall operating costs.

Q5: What types of industries can benefit from this machine?

A5: It’s ideal for recycling plants, packaging waste recovery lines, and paper reuse workshops—any facility that processes waste cardboard into reusable materials for sustainable production.

Certification