In the competitive world of packaging and printing, attention to detail can make all the difference between a standard product and a superior one. Among the many tools that play a critical role in achieving perfect results, the Corner Cutting Machine stands out as an essential piece of equipment. It may seem like a small function—rounding or cutting the corners of paper, cardboard, PVC, or laminated sheets—but in reality, precision corner cutting is crucial for both aesthetic appeal and functional integrity.

Whether you are producing packaging boxes, business cards, booklets, labels, or promotional materials, precise corner cutting enhances product quality, customer perception, and operational efficiency. As demand for professional finishing continues to rise, especially in high-end packaging and commercial printing, businesses need to understand why choosing a high-precision corner cutting machine is not just beneficial—it’s necessary.

In this article, we’ll explore the importance of precision in corner cutting machines, how they impact packaging and printing operations, what features to look for in a high-quality machine, and why Rokin’s corner cutting solutions are among the best in the industry. For businesses aiming to upgrade their finishing lines, visiting www.rokinbagmachine.com is a smart first step toward reliable, scalable, and precise cutting technology.

What Is a Corner Cutting Machine?

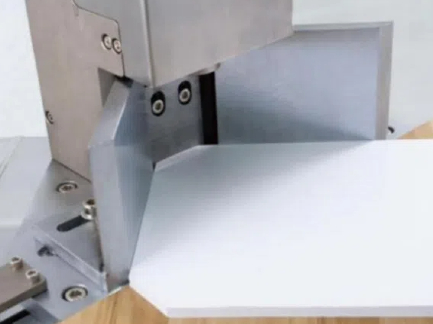

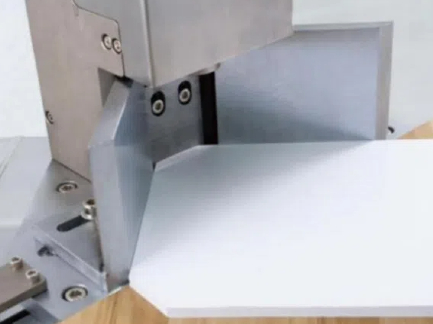

A corner cutting machine is a specialized piece of finishing equipment designed to cut the corners of various flat materials such as paper, cardboard, laminated board, plastic sheets, and other substrates. The machine can produce rounded corners, beveled edges, or custom angles, depending on the cutting die or blade used.

This type of machine is widely used in industries such as:

Packaging manufacturing

Commercial printing

Stationery and office supplies

Label and tag production

Binding and book finishing

PVC card and ID card making

Whether integrated into a fully automated line or operated manually, the purpose remains the same: to deliver consistent, clean, and smooth corner cuts that elevate the look and usability of the final product.

Why Precision Matters in Corner Cutting

1. Enhanced Aesthetic Quality

In packaging and printing, visual appeal is often the first thing a customer notices. Sharp, clean corners (whether rounded or angled) contribute to a refined and professional appearance. Even minor irregularities in corner shapes can diminish the perceived quality of the item.

For premium packaging boxes, business cards, and brochures, the slightest inaccuracy in corner cutting can disrupt the visual balance, making products look amateurish. Precision ensures that every item looks uniform, polished, and high-end—crucial factors for brand presentation and customer satisfaction.

2. Functional Integrity and Safety

Precision cutting is not just about aesthetics—it’s also about function. In packaging applications, sharp corners may pose safety risks during handling or cause damage to other items in storage or transit. Rounded corners reduce the likelihood of tearing, bending, or poking.

In printed materials such as ID cards or booklets, precision corner cutting ensures that pages turn smoothly and that edges don’t peel or wear prematurely. For products that are handled frequently, like loyalty cards or menus, corner rounding adds durability and prolongs usability.

3. Speed and Efficiency in High-Volume Production

In high-output environments, consistency is key. A high-precision corner cutting machine ensures that every cut meets exact measurements, reducing material waste and minimizing the need for manual rework or inspection.

Automated precision also translates into faster production speeds. When you can rely on your machine to deliver consistent results without adjustment or supervision, you gain time, improve workflow, and lower labor costs.

4. Meeting Industry Standards

In many sectors—especially packaging for pharmaceuticals, electronics, and luxury goods—dimensional accuracy is a compliance requirement. A small discrepancy in corner cutting could lead to regulatory issues or product rejection.

Precision cutting machines are built to adhere to industry-specific tolerances, helping manufacturers maintain quality assurance and meet customer expectations without compromise.

Key Features of a High-Precision Corner Cutting Machine

To ensure the benefits outlined above, it’s important to invest in a machine that delivers precision, reliability, and ease of use. Here are the features that define a top-tier corner cutting machine:

1. Interchangeable Dies or Blades

A versatile corner cutting machine should support different radii and angles, with quick-change dies for various corner styles. This allows one machine to handle multiple job types and custom requirements.

2. Digital Control Interface

Modern machines often include PLC touchscreens that let operators set cutting parameters with high accuracy. These digital interfaces improve control, reduce errors, and allow easy recipe recall for repeat jobs.

3. Automatic Feeding and Stacking

In automated models, precise feeding and stacking systems ensure that each sheet is aligned and processed with exact positioning. This eliminates manual alignment and supports high-speed production.

4. High-Quality Cutting Mechanism

The heart of any cutting machine is its blade system. Durable, sharp, and precisely mounted blades ensure clean, burr-free cuts. Advanced machines include self-sharpening features and wear indicators.

5. Safety and Durability

Industrial cutting machines should include emergency stops, protective covers, and overload sensors to ensure operator safety. High-quality materials in construction also ensure that the machine can run reliably for years.

Applications in Packaging & Printing

Luxury Packaging Boxes

Precise corner cutting is essential for rigid box covers and inserts. A poorly cut corner can compromise the structural integrity or visual symmetry of the box.

Business Cards and Invitations

Rounded corners on business cards are trendy and elegant. Accurate corner cutting ensures that every card is exactly the same, maintaining brand identity.

Books and Brochures

In printed booklets and brochures, rounded corners prevent paper curling, reduce wear, and provide a smooth, comfortable feel for users.

Labels and Tags

For hang tags, product labels, and price cards, corner cutting can help the items look more finished and reduce the risk of tearing during handling.

Plastic and PVC Cards

From membership cards to gift cards, precision is mandatory. Irregular cuts can make cards look cheap or damage readers in POS systems.

Why Choose Rokin’s Corner Cutting Machines?

When it comes to combining precision, speed, and value, Rokin has become a trusted name in the packaging and printing machinery industry. Their corner cutting machines are designed with advanced features, durable components, and smart automation to meet the demands of modern production lines.

Whether you're a small print shop or a large-scale packaging manufacturer, Rokin offers solutions that can be tailored to your exact needs. Their machines are engineered for easy operation, quick setup, and long-term reliability, making them a smart investment for businesses looking to scale efficiently.

To explore Rokin’s latest models and request a custom solution, visit www.rokinbagmachine.com. Their expert team will guide you through the options and help you find the right machine to meet your production goals.

Conclusion

In the dynamic world of packaging and printing, precision is not optional—it’s essential. A high-quality corner cutting machine ensures that every product you deliver looks sharp, feels premium, and meets the functional and aesthetic standards your clients expect.

From improving the customer experience to increasing your operational efficiency, precision corner cutting delivers measurable benefits across the board. As demand for high-end packaging and custom print products continues to rise, now is the time to upgrade your finishing equipment.

Choose a machine that not only meets your current needs but positions your business for future growth. Explore the full range of precision corner cutting solutions at www.rokinbagmachine.com and discover how Rokin can help you stay ahead of the curve in competitive global markets.