Introduction

As businesses and consumers become more eco-conscious, paper bags have gained significant traction. Their environmental benefits make them an ideal alternative to plastic.

In this article, we’ll explore the different types of paper bags and their various uses in packaging. You’ll learn about their materials, applications, and how to choose the right one for your needs.

What Are Paper Bags?

Definition and Overview

A paper bag is a simple and functional packaging solution made primarily from paper. They are used for carrying and transporting a wide variety of items across industries. Historically, paper bags have been popular for their eco-friendliness and strength, making them a reliable alternative to plastic bags. The versatility of paper bags, ranging from lightweight to heavy-duty versions, caters to different product types, whether food, clothing, or other retail goods.

Types of Materials Used

Paper bags are made from several types of materials, each offering distinct benefits for different uses. The most common types of paper materials used in manufacturing paper bags include:

● Kraft Paper: Known for its strength and durability, Kraft paper is the most commonly used material in paper bag production. It is made from wood pulp and is biodegradable and recyclable.

● Recycled Paper: Recycled paper bags are made from post-consumer waste and are often used to promote eco-friendly practices.

● Coated Paper: Coated paper bags are treated with a layer of coating to enhance their appearance and strength. They are often used for bags that require high print quality, such as branded bags.

These materials are chosen based on the requirements for strength, eco-friendliness, and visual appeal.

Common Types of Paper Bags

Flat Paper Bags

Flat paper bags are some of the most basic and commonly used paper bags. These bags are created from a single piece of paper that is folded and sealed on the sides. The top remains open for easy filling. Due to their simplicity, flat bags are cost-effective and easy to produce. They are widely used in retail for items like greeting cards, small accessories, and snacks.

The flat design of these bags allows for efficient storage, as they can be stacked easily without taking up too much space. Flat bags are particularly popular in the food industry for packaging dry foods and small takeaway items.

D-Cut Paper Bags

D-Cut paper bags are easily recognizable due to the D-shaped die-cut handle at the top. This unique feature allows customers to carry items comfortably while maintaining the bag's strength. The D-shape makes it easy to access the contents, making these bags a popular choice in food packaging and retail.

These bags are commonly used for takeaway food items like sandwiches, snacks, or baked goods. The D-shaped opening provides a convenient way for customers to grab items without hassle. Additionally, D-cut bags are also used for retail purposes such as small gift bags or packaging for accessories.

Square Bottom Paper Bags

Square bottom paper bags are also known as SOS bags (Self-Opening Style) due to their ability to stand upright when filled. These bags have a flat, square base, making them more stable and able to carry heavier items without tipping over. This feature makes them an excellent choice for food packaging and retail products.

Square bottom paper bags are commonly used in grocery stores for bulkier items like fruits, vegetables, or packaged goods. They are also a popular option in the food industry for packaging dry goods like flour, sugar, or grains. The stable bottom helps prevent spillage, making them ideal for more substantial products.

Paper Bags with Handles

Paper bags with handles are widely used in retail and fashion industries. These bags typically come with either twisted paper handles, flat handles, or cord handles, each offering varying levels of durability. The addition of handles makes these bags easier to carry and provides a more comfortable experience for customers.

These bags are often seen in stores selling clothing, accessories, or gifts. They offer a more upscale appearance compared to flat bags, and businesses often use them for branded packaging. The handles can be customized with logos or other design elements to promote a brand effectively.

Paper Bags with Plastic Windows

Paper bags with plastic windows are an innovative solution for showcasing the product inside without opening the bag. These bags are often used in the food industry, particularly for bakery items like bread, pastries, or cakes, as they allow customers to view the contents without compromising the bag’s protective features.

The plastic window is typically made from polypropylene or cellophane, which is heat-sealed onto the paper bag. The window is customizable in size and shape, making it a flexible option for various industries that require product visibility for marketing purposes.

Satchel Paper Bags

Satchel paper bags are easily recognizable by their unique fold-over flap closure. These bags are often sealed with an adhesive or sticker, providing a tamper-evident feature. The fold-over design helps keep the contents fresh, making these bags a common choice in food packaging.

Satchel paper bags are widely used for packaging snacks, baked goods, and small retail items like jewelry or stationary. The ability to reseal these bags makes them ideal for keeping food products fresh and preventing contamination, which is particularly important in the food and pharmaceutical industries.

V-Bottom Paper Bags

V-bottom paper bags feature a distinct V-shaped fold at the bottom, giving the bag a triangular base. This design allows the bag to stand upright, providing easy access to the contents. The V-shaped design also makes these bags easy to store and fill, as the base can be opened quickly.

These bags are commonly used in retail for packing lightweight goods such as clothing, accessories, or small electronics. V-bottom bags are also popular in the food industry for packaging items like bread or pastries, providing stability during storage and transportation.

Greaseproof Paper Bags

Greaseproof paper bags are designed to withstand the oils and moisture that often accompany food items. These bags are treated with a special coating or are made from materials that prevent grease from soaking through, ensuring that the bag remains clean and functional.

They are commonly used in the fast food industry for items like burgers, fries, or fried snacks, where oil resistance is crucial. Greaseproof paper bags help preserve the freshness of food while keeping the exterior clean and dry, making them a popular choice for quick-service restaurants and food vendors.

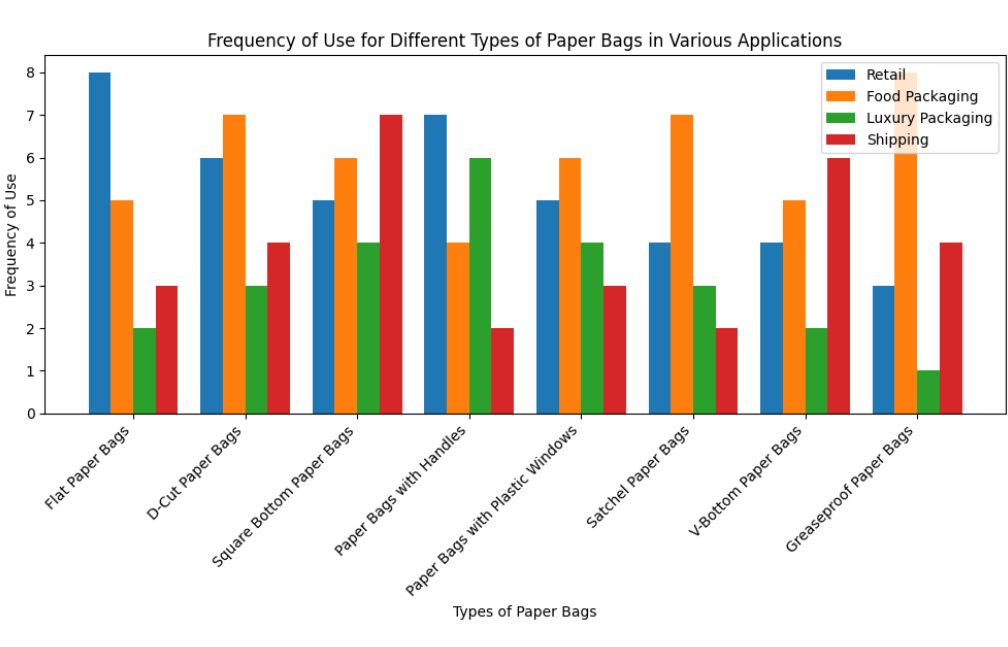

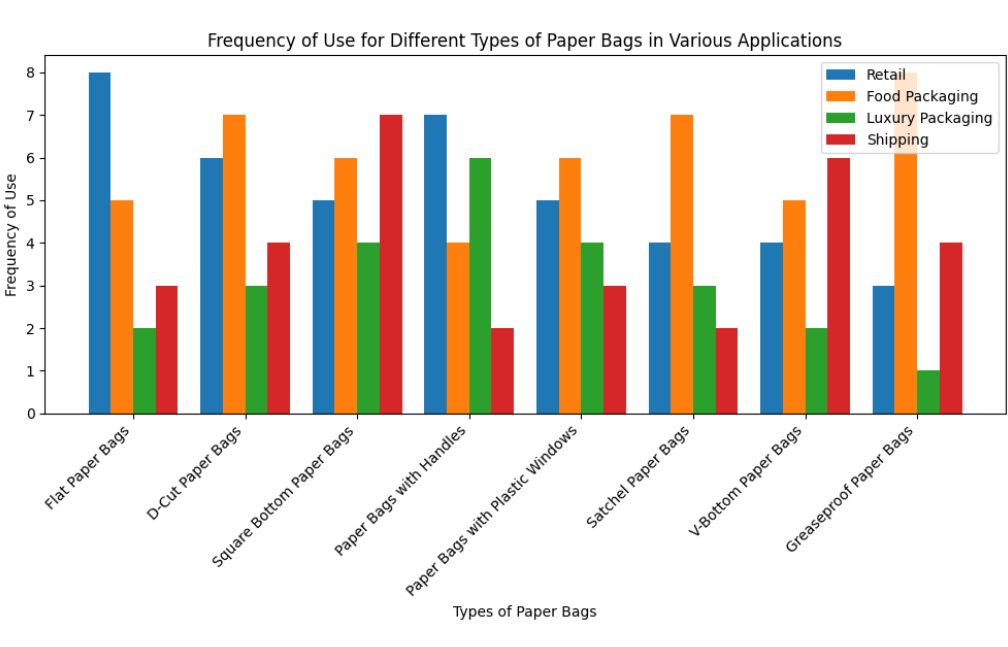

Type of Paper Bag | Main Characteristics | Common Uses |

Flat Paper Bags | Simple, no gussets, cost-effective | Retail, food packaging, e-commerce |

D-Cut Paper Bags | Die-cut handle, easy to open | Retail stores, food packaging, gift bags |

Square Bottom Paper Bags | Flat, stable base, ideal for heavy items | Grocery stores, food packaging, shipping |

Paper Bags with Handles | Different handle types (twisted, flat, cord) | Retail, fashion, luxury packaging |

Paper Bags with Plastic Windows | Transparent window, allows product visibility | Food packaging, retail stores, gifts |

Satchel Paper Bags | Fold-over closure, secure and fresh | Food packaging, pharmaceuticals |

V-Bottom Paper Bags | V-shaped bottom, easy to store and fill | Food packaging, retail stores |

Greaseproof Paper Bags | Resistant to grease and moisture | Fast food, bakery, snacks |

Key Considerations for Choosing the Right Paper Bag

Product Type and Usage

When choosing a paper bag, it is essential to consider the type of product being packaged. Heavier items may require a more durable option like square-bottom or double-layer paper bags, while lightweight products can be packaged in flat or D-cut bags. Additionally, food products may require greaseproof or paper bags with plastic windows for better visibility and protection.

Durability and Customization

Durability is an essential factor when selecting a paper bag. Products that require more protection during transit, such as fragile or perishable items, should be placed in sturdier bags with additional layers. Customization options also play a crucial role in branding. Companies often opt for custom-printed paper bags to promote their brand identity while offering practical packaging solutions.

Environmental Impact

Eco-consciousness is a growing priority for businesses and consumers alike. Choosing paper bags made from recycled materials or those that are biodegradable can help reduce the environmental footprint. By opting for paper bags instead of plastic, businesses can contribute to sustainability efforts and attract environmentally conscious consumers.

Consideration | Key Factors | Recommendation |

Product Type and Usage | Weight, size, fragility | Choose bags that match the product’s specific characteristics |

Durability and Customization | Strength of material, design options | Consider customization for branding and durability needs |

Environmental Impact | Materials used (e.g., recycled, biodegradable) | Opt for eco-friendly, recyclable, and sustainable materials |

Advantages and Disadvantages of Paper Bags

Benefits of Using Paper Bags

Paper bags are known for their strength, versatility, and biodegradability. They are an environmentally friendly alternative to plastic bags and can be recycled multiple times. Paper bags are also customizable, allowing businesses to incorporate their branding. The positive environmental impact of using paper bags appeals to consumers who prioritize sustainability.

Limitations of Paper Bags

While paper bags offer many benefits, they also have limitations. They are typically less durable than plastic bags, especially when exposed to water or moisture. Some paper bags, like flat bags, may not be suitable for heavier items unless reinforced. Additionally, paper bags can be more expensive to produce compared to plastic bags, which can be a consideration for businesses on a budget.

Trends and Innovations in Paper Bag Design

Eco-friendly Packaging Trends

As sustainability continues to be a top priority, the demand for eco-friendly packaging solutions has grown. Paper bags, made from renewable materials and designed to be recyclable or compostable, are a preferred option for businesses looking to reduce their environmental impact. Innovations in design, such as the use of biodegradable coatings or recycled paper, are helping paper bags become even more eco-friendly.

Customization and Printing Advancements

Advancements in printing technology have made it easier for businesses to customize paper bags with logos, designs, and branding elements. High-quality printing techniques allow for vibrant colors and detailed graphics, making paper bags an effective marketing tool. Custom paper bags also help create a unique consumer experience, promoting brand recognition and customer loyalty.

Conclusion

Paper bags are a versatile, eco-friendly, and customizable packaging solution for various industries. They provide a sustainable alternative to plastic, offering different types and materials for diverse needs. By choosing the right paper bag, businesses can meet packaging requirements and boost brand image while supporting environmental sustainability.

As companies prioritize sustainability, paper bags are the perfect choice. Strong, customizable, and environmentally friendly, they align with green initiatives and enhance brand appeal. For businesses looking to optimize their packaging, Wenzhou Rokin Machinery CO. Ltd. offers high-quality machinery solutions for producing paper bags efficiently.

FAQ

Q: What are paper bags used for?

A: Paper bags are versatile and used for packaging food, retail items, gifts, and shipping products. They are eco-friendly and recyclable.

Q: What are the different types of paper bags?

A: Common types of paper bags include flat bags, D-cut bags, square bottom bags, paper bags with handles, and greaseproof bags, each suited for different uses.

Q: Why should I choose a paper bag for packaging?

A: Paper bags are biodegradable, recyclable, and customizable, offering an eco-friendly alternative to plastic bags while enhancing brand image.

Q: Are paper bags strong enough for heavy items?

A: Yes, certain types like double-layered and square bottom paper bags are designed to carry heavier products, making them ideal for bulk packaging.

Q: How do paper bags contribute to sustainability?

A: Paper bags reduce plastic waste, are biodegradable, and are made from renewable resources, helping businesses align with green initiatives.

Q: Can paper bags be customized for branding?

A: Yes, paper bags can be easily customized with prints, logos, and designs to boost brand visibility and appeal to consumers.