Introduction

Plastic bags are everywhere, from your shopping bag to food packaging. Despite concerns over environmental impact, they remain essential. Their durability, versatility, and cost-effectiveness make them a staple across industries.

In this article, we will explore the different types of plastic bags, their materials, design features, and where they are most commonly used. By the end, you will have a better understanding of which plastic bag type suits your needs.

What Are Plastic Bags?

Definition of Plastic Bags

Plastic bags are flexible containers made from polymer films such as polyethylene (PE) and polypropylene (PP). They are designed to carry, store, or protect products, making them essential in a variety of settings. These bags are known for their lightweight nature, durability, and ability to be sealed or closed easily, making them a practical choice for both consumers and businesses alike.

The Versatility of Plastic Bags

Plastic bags come in many forms and serve numerous functions. From lightweight shopping bags to heavy-duty industrial sacks, they are highly adaptable and can be customized for specific uses. Their ability to preserve food freshness, protect items from damage, and facilitate easy handling makes them indispensable in packaging. Plastic bags are also cost-effective, offering manufacturers and retailers a low-cost option for product storage and transportation.

Types of Plastic Bags for Packaging

Flat Plastic Bags

Design and Features

Flat plastic bags are one of the most commonly used types of plastic packaging. These bags typically feature three sealed sides and one open end, which can be closed with heat sealing or adhesive tape. They are generally made from LDPE (Low-Density Polyethylene) or HDPE (High-Density Polyethylene), depending on the strength and flexibility required for the application. These bags are simple in design but highly effective for packaging a wide range of products.

Common Applications

Flat plastic bags are frequently used for packaging food items like sandwiches, fruits, and vegetables. They are also widely used in retail packaging for non-food products, such as clothing, books, and small electronics. Their simplicity, low cost, and versatility make them a popular choice across various industries, especially in retail and food packaging.

Gusseted Plastic Bags

Design and Features

Gusseted plastic bags are designed with folds or "gussets" on the sides, allowing the bag to expand when filled. This feature increases the bag's capacity, making it ideal for packaging bulkier or oddly shaped items. Gusseted bags are typically made from LDPE or HDPE and are known for their ability to hold more than flat bags of the same size.

Common Applications

These bags are widely used for packaging larger items such as clothing, hardware, and fresh produce. Their ability to expand makes them particularly useful for items that require additional space, such as bulk fruits and vegetables. Gusseted bags also make excellent display packaging, as the expanded sides improve visibility and make the products more accessible to consumers.

Stand-Up Pouches

Design and Features

Stand-up pouches are a type of gusseted bag with a flat, gusseted bottom that allows them to stand upright when filled. These pouches are typically made from multi-layer materials, combining plastic, aluminum foil, or paper to provide superior barrier properties that protect the contents from moisture, light, and oxygen.

Common Applications

Stand-up pouches are commonly used for packaging snacks, beverages, pet food, and cosmetics. Their ability to stand upright makes them ideal for retail shelves, as they offer better product visibility and space efficiency. Many stand-up pouches also feature resealable closures, which help preserve product freshness and make them a convenient option for consumers.

Reclosable Plastic Bags (Ziplock Bags)

Design and Features

Reclosable plastic bags, commonly known as ziplock bags, feature a resealable closure system that allows the bag to be securely sealed multiple times. These bags are typically made from polyethylene, which provides durability and flexibility. The sealing mechanism is simple yet effective: a zipper-like track along the top of the bag, which can be easily opened and closed without the need for additional sealing equipment. This feature makes them particularly convenient for items that need to be accessed repeatedly while maintaining freshness, preventing contamination, and minimizing spillage.

Common Applications

Reclosable plastic bags are extremely versatile and are used across various sectors. In the food industry, they are commonly used for storing snacks, frozen vegetables, fruits, and grains, keeping the items fresh for longer periods. They are also popular for packaging non-food items such as jewelry, small electronics, and craft materials, as they provide an efficient and organized way to store and transport goods. The ability to open and reseal the bags makes them particularly convenient for both consumers who need easy access and businesses that require efficient packaging solutions for various products.

Drawstring Plastic Bags

Design and Features

Drawstring plastic bags come with a closure system that incorporates a string or cord to secure the bag's opening. This closure method eliminates the need for additional sealing equipment, making these bags quick and easy to use. Typically made from materials like LDPE (Low-Density Polyethylene), these bags offer flexibility and practicality. The drawstring closure ensures that the contents are securely sealed, while also allowing for easy access when needed. This design makes them an ideal choice for items that may need to be opened and closed frequently or stored temporarily.

Common Applications

Drawstring plastic bags are commonly used in retail promotions, gift packaging, and lightweight item storage. These bags are particularly useful for packaging small products like shoes, toys, and other consumer goods, providing an easy-to-carry and convenient packaging option. In addition, they are often used for packaging promotional giveaways or items that require temporary storage or presentation. The drawstring closure feature ensures that the bag can be quickly and securely closed, making it a practical solution for both consumers and businesses.

T-Shirt Plastic Bags

Design and Features

T-shirt plastic bags are named for their design, which resembles the shape of a T-shirt, complete with handles at the top for easy carrying. These bags are made from flexible polyethylene and come in various sizes and thicknesses to suit different packaging needs. They are typically lightweight but durable, offering a practical solution for storing or transporting goods. T-shirt bags are designed to be easy to carry, with the handles making them a convenient choice for shoppers and retailers alike.

Common Applications

T-shirt plastic bags are widely used in grocery stores, retail clothing shops, and during promotional events. Their ease of use and quick filling capabilities make them a popular choice for packaging groceries, clothing, and other lightweight products. These bags are also a common solution for bulk distribution in supermarkets, providing customers with an efficient and cost-effective way to carry goods. In addition, t-shirt bags are often used in retail environments to package promotional items, as they are easy to customize with logos or brand messages.

Plastic Wicketed Bags

Design and Features

Plastic wicketed bags are attached to a wire frame (called a wicket) that allows the bags to be easily loaded into automated packaging machines. This design is particularly useful in high-efficiency packaging environments where speed and volume are essential. Wicketed bags are typically made from polyethylene and can be customized to suit various product types. The bags are designed to be quickly and easily separated from the wicket, allowing for smooth operations in automated systems.

Common Applications

Wicketed bags are commonly used for packaging bakery items, fresh produce, and small hardware products. Their ability to be quickly loaded into machines makes them ideal for large-scale manufacturing or retail settings that require packaging efficiency. Wicketed bags are especially useful in automated production lines, where speed and accuracy are critical for maintaining product flow and minimizing downtime.

Bubble Bags

Design and Features

Bubble bags are designed with an outer plastic layer that contains air-filled bubbles, providing cushioning and protection for fragile items during shipping and transport. The bubbles act as shock absorbers, preventing products from being damaged by impacts or vibrations. These bags are lightweight yet highly effective at safeguarding delicate items. The air-filled layer also ensures that the bags remain lightweight, reducing shipping costs without compromising on protection.

Common Applications

Bubble bags are widely used for packaging fragile items such as electronics, glassware, ceramics, and other breakable goods. The cushioning effect provided by the bubbles makes these bags ideal for shipping products that require extra protection from physical damage. Additionally, the lightweight nature of bubble bags helps to reduce overall shipping costs, making them a cost-effective option for companies that need to send delicate products securely.

Metalized Bags

Design and Features

Metalized bags are made with a multi-layer structure that incorporates a layer of aluminum foil. This aluminum layer enhances the bag’s ability to block out moisture, light, and oxygen, which are often the main factors that cause food products and other sensitive items to degrade over time. The metalized layer provides superior protection, extending the shelf life of the contents and preserving freshness.

Common Applications

Metalized bags are frequently used for packaging products that need to maintain their quality over a long period, such as coffee, snacks, and other perishable items. The aluminum foil layer helps to preserve the flavor and freshness of the contents, making metalized bags ideal for long-term storage. These bags are also used in the packaging of pharmaceuticals and other items that are sensitive to environmental conditions.

Pinch Bottom Bags

Design and Features

Pinch bottom bags are sealed by folding and pinching the bottom of the bag, creating a secure closure without the need for adhesives. These bags are typically made from kraft paper or polyethylene and are ideal for packaging bulk products. The pinch-bottom design is simple but highly effective, ensuring that the contents remain securely sealed and protected during transportation and storage.

Common Applications

Pinch bottom bags are commonly used for packaging bulk products like grains, pet food, and pharmaceuticals. The design ensures a strong, secure seal that protects the contents from moisture, dirt, and other contaminants during storage and shipping. These bags are particularly popular in industries where bulk items need to be packaged quickly and efficiently, such as in agriculture and manufacturing.

Factors to Consider When Choosing Plastic Bags for Packaging

Material Properties

The material of the bag plays a crucial role in its performance. HDPE, LDPE, and PP are the most commonly used materials, each offering different levels of strength, flexibility, and durability. HDPE is ideal for heavy-duty applications, while LDPE is commonly used for food packaging due to its flexibility and clarity. It is important to consider the intended use of the bag to select the most suitable material.

Material | Properties | Common Uses |

HDPE | Strong, stiff, lightweight, translucent | Grocery bags, trash bags, hardware packaging |

LDPE | Flexible, clear, easy to seal | Food packaging (bread, produce), contractor bags |

LLDPE | Tough, impact-resistant, flexible | Produce bags, shipping envelopes, pallet covers |

PP | High clarity, rigid, moisture barrier | Apparel bags, food packaging (snacks), medical packaging |

PLA | Biodegradable, compostable | Eco-friendly shopping bags, disposable food wrap |

Laminated Films | High barrier properties, premium feel | Stand-up pouches, medical supplies |

Intended Use Environment

Different environments may require different types of bags. For instance, bags used in retail settings should be durable and easy to handle, while bags used in food packaging need to provide moisture and odor barriers. Understanding the product’s storage and transport needs will help guide the selection of the right bag. Bags used for industrial purposes may require more robust materials, while those for retail packaging may prioritize aesthetics.

Bag Design

The design of the bag should match the product being packaged. Flat bags work well for smaller, lightweight items, while gusseted and stand-up pouches are better suited for larger or bulkier items. Consideration of product visibility, ease of use, and space efficiency are key factors in bag design. For example, clear bags may be preferred for showcasing products, while opaque bags may be better for items that require protection from light.

Sustainability Considerations

As environmental concerns continue to grow, choosing eco-friendly plastic bags has become increasingly important. Many businesses are opting for biodegradable or recyclable bags to reduce their environmental impact while still maintaining functionality and cost-effectiveness. Sustainable materials like biodegradable polyethylene or compostable options can help businesses align with consumer expectations for environmentally responsible packaging.

Plastic Bag Regulations and Compliance

Global Regulations

Plastic bag use is heavily regulated in many countries due to environmental concerns. Various regions have enacted bans, taxes, or restrictions on single-use plastic bags. Some places are encouraging the use of biodegradable or recyclable options to reduce the environmental footprint. Businesses should be aware of local regulations to ensure compliance and avoid penalties.

Industry-Specific Regulations

Different industries, such as healthcare, pharmaceuticals, and electronics, have specific regulations regarding packaging materials. For example, medical and pharmaceutical packaging requires additional considerations for sterility and safety. Companies in these sectors must ensure that their plastic bags meet the necessary standards for protecting sensitive products.

Conclusion

Plastic bags continue to be a key part of packaging solutions across industries. From flat bags to stand-up pouches, each type serves specific functions. As demand for sustainable packaging grows, the industry is evolving to offer eco-friendly alternatives without compromising functionality. Whether used in food packaging, retail, or industrial sectors, plastic bags remain essential. Companies like Wenzhou Rokin Machinery CO. Ltd. offer reliable machinery for efficient plastic bag production, enhancing packaging operations with high-quality, cost-effective solutions.

FAQ

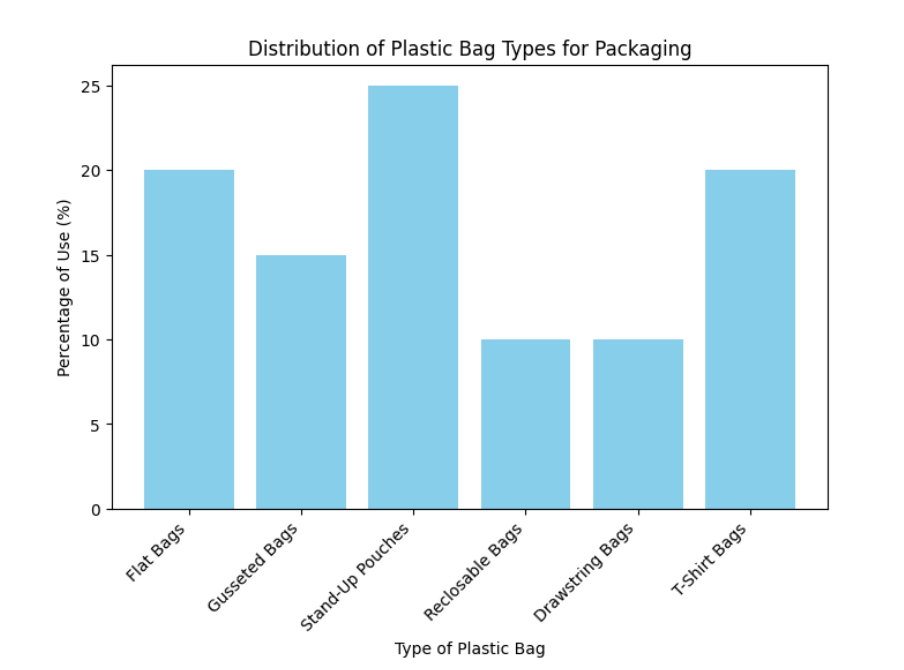

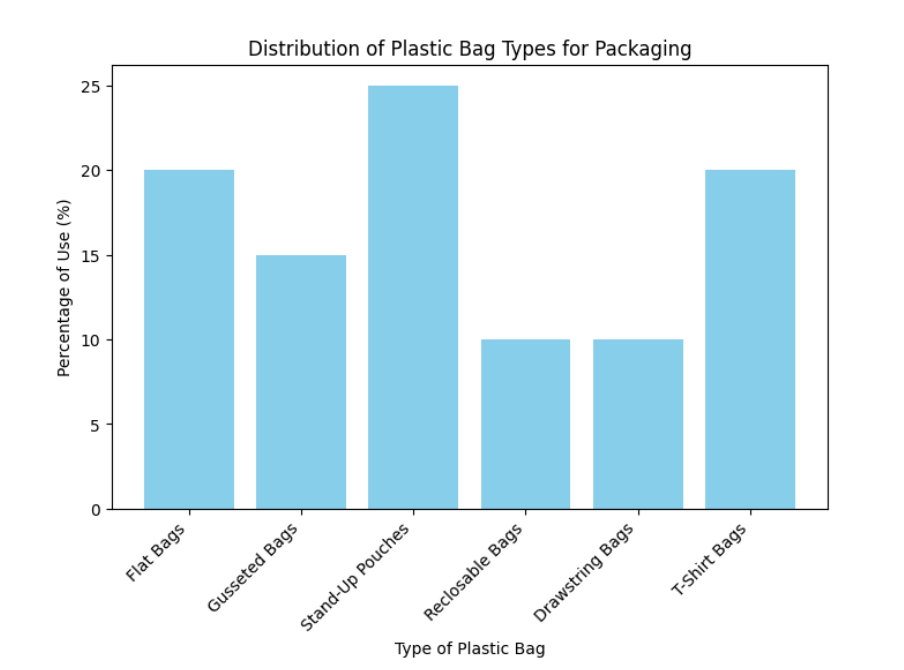

Q: What are the different types of plastic bags for packaging?

A: There are various types of plastic bags for packaging, including flat bags, gusseted bags, stand-up pouches, reclosable bags, drawstring bags, and T-shirt bags. Each serves a specific function based on the product being packaged.

Q: How do reclosable plastic bags work?

A: Reclosable plastic bags, also known as ziplock bags, feature a sealable closure that allows users to open and close the bag multiple times, keeping contents secure and fresh.

Q: Why are plastic bags commonly used in food packaging?

A: Plastic bags, such as LDPE or HDPE bags, are commonly used in food packaging because they help preserve food freshness, are flexible, and offer cost-effective solutions.

Q: What materials are used to make plastic bags for packaging?

A: Common materials used in plastic bags for packaging include HDPE, LDPE, LLDPE, and PP. Each material provides specific benefits such as durability, flexibility, and moisture resistance.

Q: Are there eco-friendly options for plastic packaging?

A: Yes, as demand for sustainable packaging grows, many manufacturers are producing biodegradable or recyclable plastic bags, reducing environmental impact while maintaining functionality.