The packaging industry is undergoing a major shift toward eco-friendly, efficient, and high-quality solutions. Factories that want to stay competitive must find ways to streamline production while maintaining consistent product standards. A Paper Bag Making Machine offers a strategic advantage, allowing factories to produce high-quality bags with speed, precision, and minimal waste. Rokin’s machines, known for their durability, smart automation, and versatility, are ideal for producing flat bags, block-bottom bags, and handle bags. Let’s explore why investing in a paper bag making machine is the best choice for your factory.

High Production Efficiency

Efficiency is the cornerstone of successful manufacturing. Rokin paper bag machines are designed to maximize output while reducing manual labor and downtime.

Faster Manufacturing Cycles

One of the key productivity advantages of Rokin machines is speed. Fully automatic models can produce between 50 to 600 bags per minute, depending on bag type and size. High-speed models can reach even greater production rates, ideal for large-scale operations. This rapid production allows factories to handle bulk orders efficiently and respond quickly to market demands. By reducing the time required for each production cycle, these machines enable businesses to take on more orders without increasing labor costs, making the production line more profitable. Fast cycles also help reduce lead time for clients, improving customer satisfaction and retention.

Minimized Human Error

Manual paper bag production is prone to errors such as inconsistent sizes, uneven folding, and misaligned handles. Rokin’s automated machines solve this by precisely controlling every step of production. Sensors and intelligent control systems ensure that paper feeding, cutting, folding, sealing, and handle attachment are accurate and consistent. Minimizing human intervention reduces material waste, lowers the rate of defective products, and saves time that would otherwise be spent correcting mistakes. This reliability ensures that every bag meets quality standards, which strengthens the factory’s reputation and builds trust with clients who expect high-quality packaging.

Scalable Production for Growing Businesses

Rokin machines are designed to grow with your business. As demand increases, production speed and output can be adjusted without the need for additional machinery or workforce. This scalability allows factories to handle seasonal spikes, large bulk orders, or new product lines efficiently. By providing flexible settings for bag size, type, and production speed, the machines adapt to diverse production needs, enabling factories to expand their operations without significant capital investment. This adaptability ensures long-term value and supports sustainable business growth.

Consistent Quality and Precision

Delivering uniform, high-quality paper bags is essential for customer satisfaction and brand credibility. Rokin machines provide precise and reliable production.

Uniform Bag Dimensions

Consistency is critical for professional packaging. Rokin machines maintain exact bag dimensions for flat-bottom, block-bottom, and handle bags, ensuring every unit meets specifications. This precision is particularly important for retailers and food service businesses that require standardized packaging. Uniform bags enhance the visual appeal of products, reduce returns due to defects, and allow for smoother logistics and stacking during transport. By consistently producing bags of the same quality, factories can strengthen client relationships and increase repeat orders.

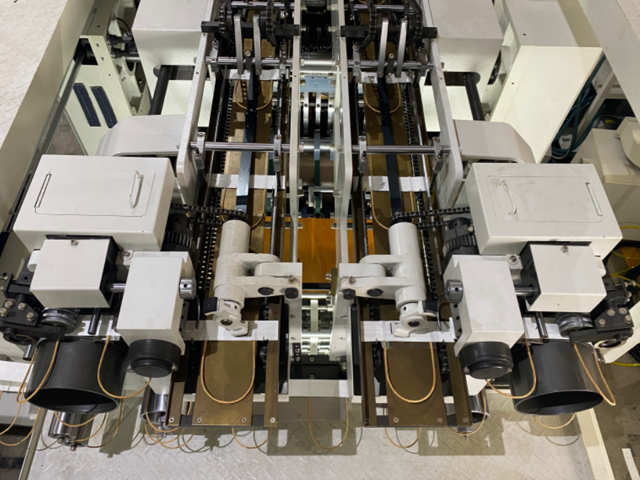

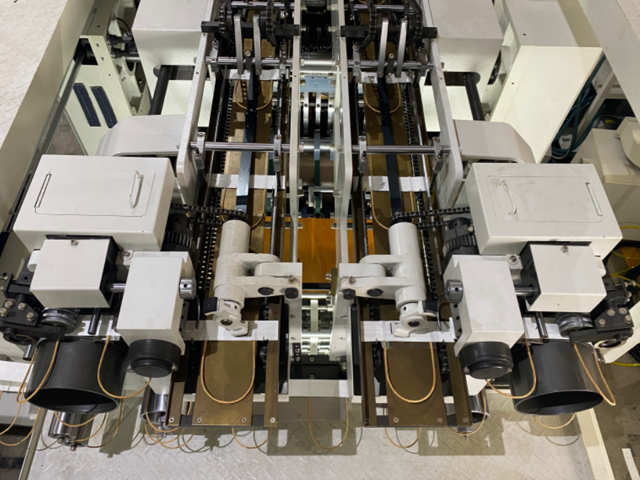

Advanced Folding and Sealing Technology

Rokin machines use intelligent folding and bottom sealing mechanisms to create durable, high-quality bags. The systems automatically adjust folding angles and sealing pressure based on bag type and paper thickness. This technology ensures strong bottom seals, sharp edges, and reliable structural integrity for each bag. Advanced mechanisms also reduce material waste and rework, as the folding and sealing are precise every time. High-quality finishes help businesses deliver products that meet consumer expectations and enhance brand image.

Compliance with Industry Standards

Factories supplying retailers, supermarkets, or food industries must meet strict packaging standards. Rokin machines are engineered to produce bags that comply with safety, durability, and environmental regulations. Consistent adherence to standards reduces the risk of rejected orders and strengthens factory credibility. Compliance with industry norms also enables factories to access larger clients and international markets, where stringent packaging standards are mandatory, thereby increasing market reach and business opportunities.

Eco-Friendly and Sustainable Production

Environmental responsibility is no longer optional; it is essential. Rokin machines support sustainable production through efficient use of biodegradable paper materials.

Support for Biodegradable Paper

Paper bags are environmentally friendly alternatives to plastic bags. Rokin machines are compatible with various types of recyclable and biodegradable paper, enabling factories to produce eco-friendly products. By offering sustainable packaging solutions, businesses meet consumer demand for environmentally conscious products and reduce their ecological footprint. This advantage not only strengthens brand image but also attracts clients and consumers who prioritize sustainability.

Compliance with Environmental Regulations

With increasing restrictions on plastic use in many countries, producing paper bags ensures factories remain compliant with environmental legislation. Rokin machines provide the flexibility to produce bags that meet these regulatory requirements efficiently. Compliance reduces the risk of fines, legal issues, and business disruptions, while also aligning the factory with global sustainability goals. Factories that adopt eco-friendly production gain a competitive advantage in markets where sustainability is increasingly important.

Meeting Consumer Expectations

Consumers are increasingly choosing brands that demonstrate environmental responsibility. By producing high-quality paper bags with Rokin machines, factories help their clients deliver sustainable packaging solutions. This increases customer satisfaction, fosters brand loyalty, and opens new business opportunities with companies that prioritize eco-friendly packaging. The ability to combine efficiency, quality, and sustainability positions the factory as a modern and responsible partner in the packaging supply chain.

Customization and Versatility

Every client has unique packaging needs, and Rokin machines provide the flexibility to meet those requirements efficiently.

Adjustable Bag Sizes and Types

Rokin machines allow quick adjustments for different bag sizes and types, including flat, handle, and block-bottom designs. This flexibility enables factories to serve a wider range of clients and industries, from retail and food service to supermarkets. The ability to switch between products without long setup times improves productivity and responsiveness to customer demands. Factories can also experiment with new designs, materials, or bag features to create unique packaging solutions, expanding market opportunities.

Optional Printing and Branding Integration

Some Rokin models can integrate printing systems for logos, slogans, or promotional graphics, providing added value for clients. Customizable branding helps clients differentiate their products, while factories can charge premium prices for these enhanced capabilities. Integration of printing within the same machine ensures efficiency, as bags are produced and branded in one seamless operation, saving time and labor costs.

Adaptability to Changing Market Needs

Market trends and consumer preferences evolve quickly, requiring factories to be flexible. Rokin machines allow operators to switch between bag types, sizes, or materials with minimal downtime. This adaptability ensures that the factory can respond promptly to new orders or changes in client specifications. The ability to adjust production quickly without sacrificing efficiency or quality provides a strong competitive advantage and positions the factory as a reliable supplier for diverse market needs.

Cost-Effectiveness in the Long Run

While investing in a Rokin paper bag machine requires capital, the long-term benefits far outweigh initial costs.

Reduced Labor Costs

Automation decreases the need for large teams, allowing a few skilled operators to manage the entire production line. This reduces labor expenses and reallocates human resources to supervision and quality control tasks. Over time, reduced labor costs significantly improve profitability, especially in high-volume operations. By combining high output with lower staffing requirements, factories achieve cost-efficient production while maintaining consistent quality.

Minimized Material Waste

Rokin machines optimize paper usage through precise cutting, folding, and sealing, minimizing material waste. Lower waste translates into direct cost savings, particularly for large-scale production runs where paper costs are substantial. Reduced scrap also contributes to sustainable operations, aligning financial benefits with environmental responsibility.

Durability and Reliability

Constructed with high-quality materials and engineered for continuous use, Rokin machines offer long-term reliability. Low maintenance requirements and robust design ensure consistent performance over many years, reducing the need for frequent repairs or replacement. This durability provides a high return on investment, allowing factories to maximize production efficiency and maintain high-quality output with minimal interruptions.

Conclusion

Investing in a Paper Bag Making Machine is a strategic choice for factories seeking to enhance productivity, ensure consistent quality, and meet sustainability goals. Rokin machines offer automation, high speed, precision, durability, and flexibility, making them suitable for producing flat, handle, and block-bottom bags. By improving efficiency, reducing labor costs, supporting eco-friendly practices, and providing customizable solutions, these machines position factories for long-term success in the competitive packaging market. For businesses aiming to scale operations and deliver high-quality packaging solutions, a Rokin paper bag making machine is undeniably the best choice.